Product Overview

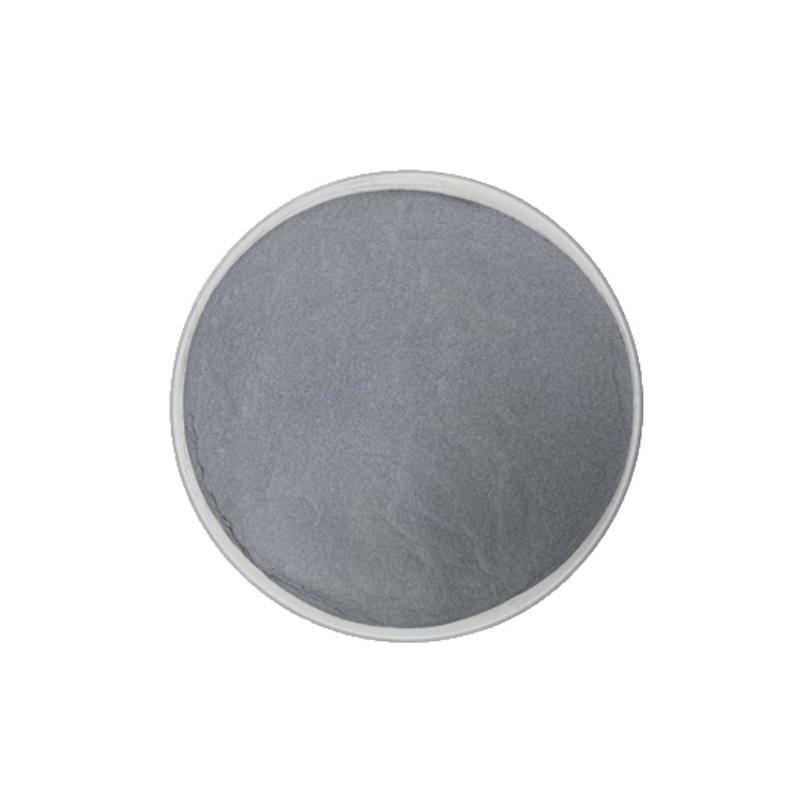

Calcium granules are silvery-white light metals with a soft texture and low density (1.54 g/cm³). They exhibit high chemical reactivity. Calcium granules have a melting point of 839±2°C and a boiling point of 1484°C. They react with water or acids to produce hydrogen gas. The surface of calcium granules naturally forms a protective oxide and nitride film, preventing further corrosion. These granules are widely used in alloy manufacturing, metallurgy, petrochemical industries, and other fields, offering significant industrial application value.

Features

- Soft texture, low density, and high chemical reactivity.

- Self-protecting by forming an oxide layer on the surface to prevent further corrosion.

- Excellent reducing properties, suitable for various industrial reactions.

Applications

Calcium granules are widely used in several industrial fields:

- Metallurgy: As a reducing agent in metallurgy, calcium granules are commonly used in the production of ferrous alloys, especially in desulfurization, deoxidation, and decarbonization processes.

- Alloy Manufacturing: In alloy production, calcium granules act as a deoxidizer, improving the purity and quality of alloys.

- Petrochemical Industry: As a dehydrating agent, calcium granules help remove moisture from petroleum, optimizing the quality of petroleum products.

- Electronics Industry: Calcium granules are used in electron tubes as a gas-absorbing agent, maintaining the performance of the tubes.

| Description | Ca | Cl | N | Mg | Cu | Ni | Mn | Si | Fe | Al |

| Calcium Turnings | 99.5 | 0.005 | 0.01 | 0.08 | 0.005 | 0.005 | 0.008 | 0.008 | 0.01 | 0.01 |

new material

new material