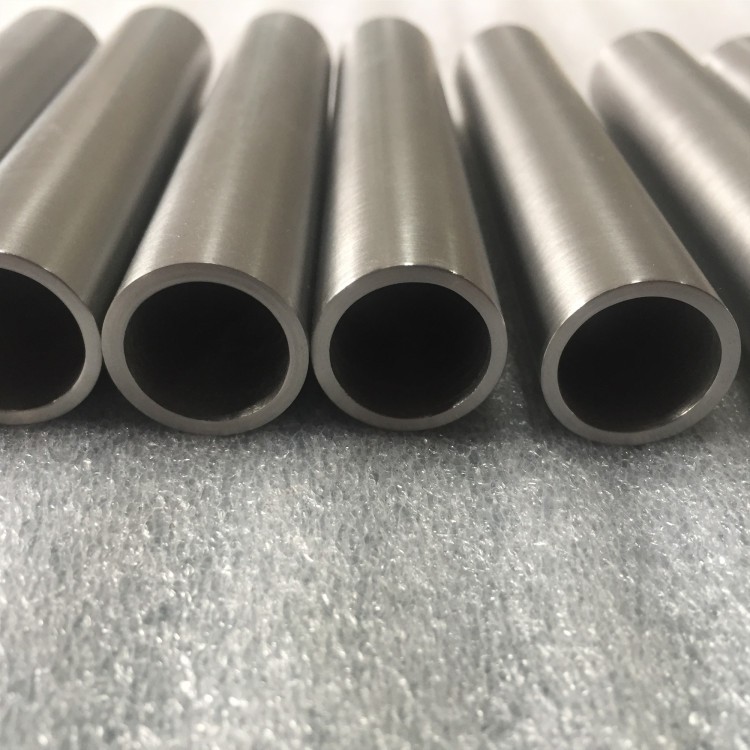

Product Overview

The tungsten tube is a tubular metal product made of high-purity tungsten, renowned for its exceptional high-temperature stability, corrosion resistance, and mechanical strength. Its ability to perform reliably in extreme conditions makes it an ideal choice for high-temperature and high-strength applications in electronics, aerospace, and industrial sectors.

Key Features

- High Melting Point: With a melting point of 3410°C, the tungsten tube maintains excellent physical performance under extreme heat.

- High Density: The tungsten tube's high density and superior mechanical strength make it suitable for high-pressure applications.

- Corrosion Resistance: Exceptional resistance to most acids and bases allows the tungsten tube to operate in harsh chemical environments.

- Excellent Conductivity: The tungsten tube efficiently conducts electricity and heat, making it ideal for electrical heating and heat exchange applications.

- Chemical Stability: Tungsten exhibits remarkable chemical stability, resisting reactions with air, water, and most chemicals at normal temperatures.

Applications

The tungsten tube is used in various high-demand fields, including:

- Electronics Industry: Used in manufacturing high-temperature electronic components, such as thermocouple protection tubes and heating elements.

- Aerospace: Tungsten tubes are applied in spacecraft engine components and high-temperature insulation due to their strength and thermal resistance.

- Chemical Industry: Ideal for corrosive chemical media as reaction vessels or chemical transport pipes.

- Medical Sector: Used in radiation shielding components for radioactive devices and other high-precision medical instruments.

- High-Temperature Processing: Suitable for components in high-temperature metallurgical equipment, such as furnace heaters and heat treaters.

- Mechanical Manufacturing: Functions as wear- and corrosion-resistant pipeline components, enhancing equipment durability and efficiency.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | Pb | <10 | ppm | |||||||

| B | Ga | Bi | <10 | ppm | |||||||

| F | Ge | Y | |||||||||

| Na | As | Th | |||||||||

| Mg | <30 | ppm | Se | Er | |||||||

| Al | <20 | ppm | Zr | Ru | |||||||

| Si | <50 | ppm | Nb | Rh | |||||||

| P | Mo | <100 | ppm | Os | |||||||

| Cl | Pd | Cd | |||||||||

| K | Ag | In | |||||||||

| Ca | <50 | ppm | Sn | <10 | ppm | ||||||

| Ti | Sb | <10 | ppm | ||||||||

| V | Ba | ||||||||||

| Cr | ppm | Hf | |||||||||

| Mn | Ta | C | 80 | ppm | |||||||

| Fe | <50 | ppm | W | Matrix | wt% | S | |||||

| Co | Pt | O | 50 | ppm | |||||||

| Ni | <30 | ppm | Au | N | 30 | ppm | |||||

| Cu | Hg | H |

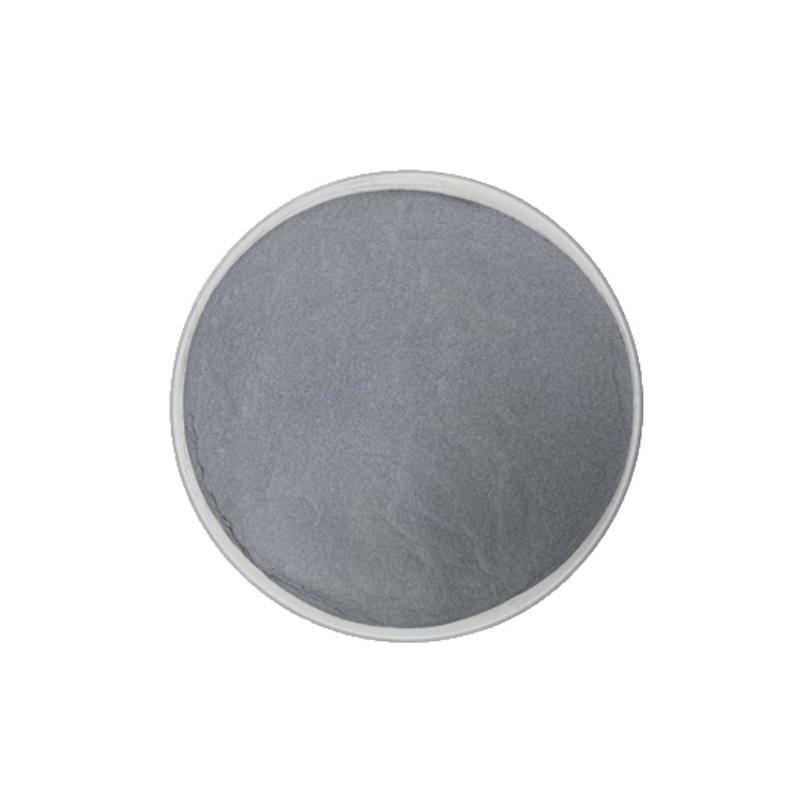

new material

new material