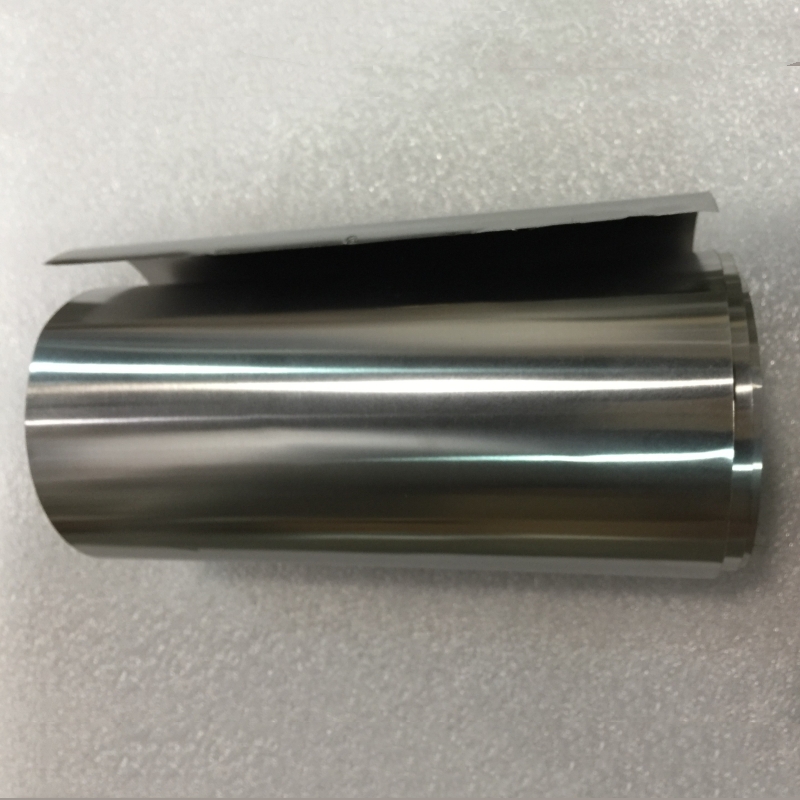

Product Overview

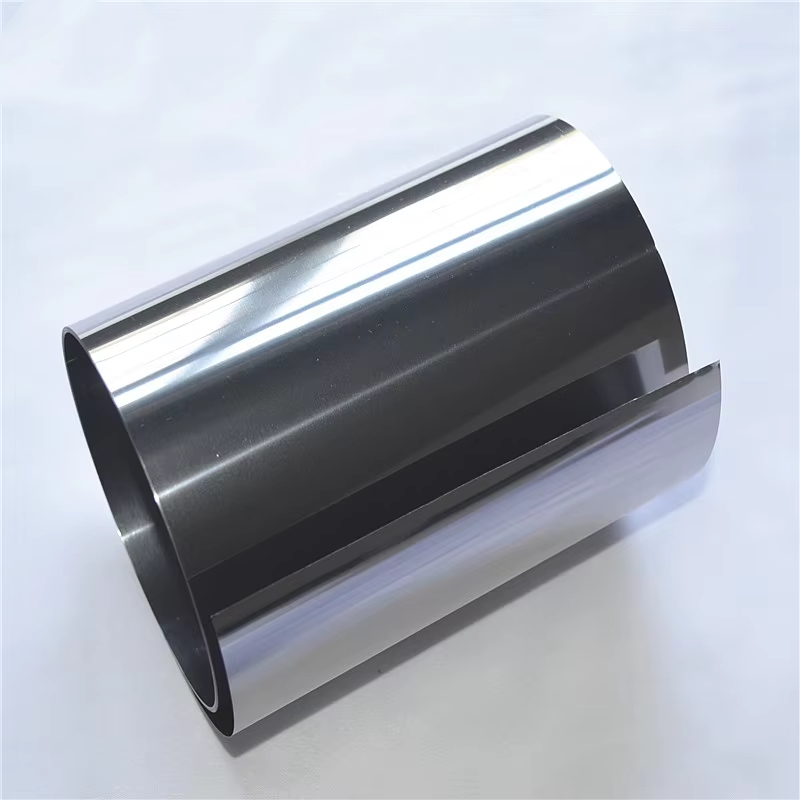

Tungsten foil is a thin sheet made from high-purity tungsten, known for its exceptional high-temperature stability, strength, and corrosion resistance. Tungsten foil is widely used in industries that require components capable of withstanding extreme temperatures and chemical reactions. It is particularly suitable for high-precision manufacturing and special environmental applications.

Key Features

- High Melting Point: Tungsten foil has a melting point of up to 3410°C, allowing it to maintain stable physical and chemical properties in high-temperature environments.

- High Density: Tungsten has a density of 19.35 g/cm³, giving the foil high strength and pressure resistance.

- Excellent Corrosion Resistance: Tungsten foil exhibits strong resistance to most acids, bases, and chemical substances, making it ideal for use in harsh operating conditions.

- Superior Conductivity: Tungsten foil effectively conducts both electricity and heat, making it suitable for electrical devices and heat exchange applications.

Applications

Tungsten foil is used in various high-performance industries, including:

- Electronics Industry: Tungsten foil is used in the manufacture of electronic components, especially for high-temperature, high-current applications, such as electrodes, heating elements, and other critical parts.

- Lighting Industry: It is used in the production of high-temperature filaments, such as halogen tungsten filaments, ensuring filament stability and longevity.

- Aerospace: Due to its excellent high-temperature resistance, tungsten foil is widely used in aerospace applications, including high-temperature insulation shields, rocket engines, and other components.

- Medical Industry: Tungsten foil is used in radiation shielding for X-ray equipment, providing effective protection from radiation.

- High-Temperature Processing: Tungsten foil is used in the manufacture of vacuum coating equipment and high-temperature reaction vessels.

- High-Precision Manufacturing: Tungsten foil’s high hardness and wear resistance make it ideal for high-precision tools and mold manufacturing.

| Main Comp.W≥99.95 | ||||||

| Other Content≤ | Fe | 0.0026 | Al | 0.0006 | Si | 0.001 |

| Ca | 0.001 | Ni | 0.0009 | O | 0.0018 | |

| Cu | 0.0005 | N | 0.0015 | Pb | 0.0001 | |

| Sn | 0.0001 | Sb | 0.001 | As | 0.001 | |

| Cd | 0.0001 | Mg | 0.0006 | C | 0.002 | |

| Bi | 0.0001 | Mo | 0.003 | |||

new material

new material