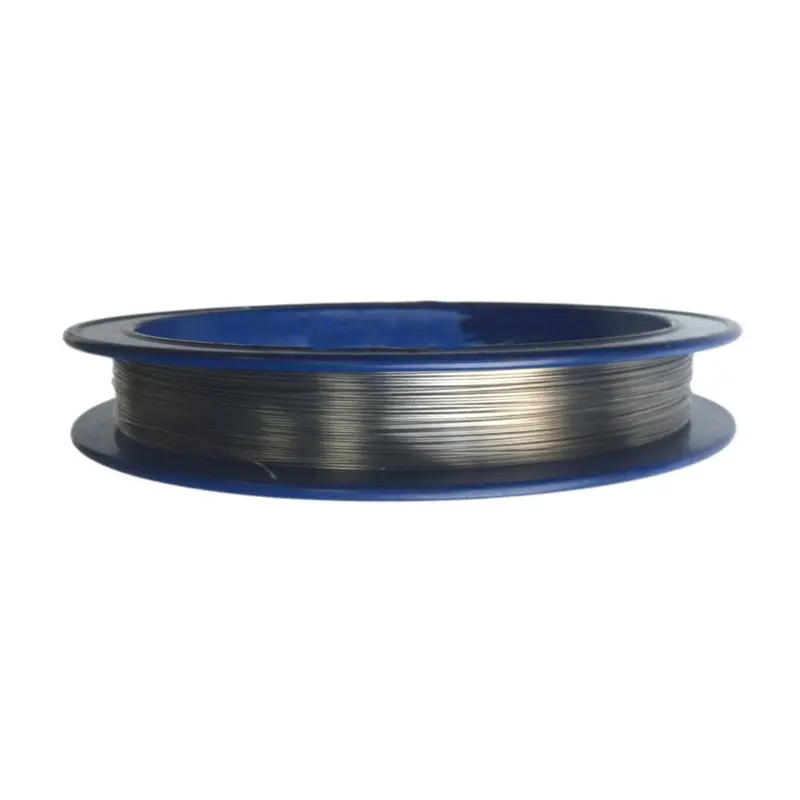

Product Overview

Tantalum wire is a fine filament made from high-purity tantalum material, known for its exceptional high-temperature resistance, corrosion resistance, and excellent electrical properties. It is widely used in various industries such as electronics, chemicals, and aerospace, particularly in high-temperature and corrosive environments, where it performs exceptionally well.

Features

- High Melting Point: Tantalum wire has a melting point of up to 2996°C, allowing it to withstand extreme temperature conditions

- Excellent Ductility: Tantalum wire can be processed into very fine filaments, meeting various precision requirements

- Low Thermal Expansion Coefficient: The low thermal expansion coefficient makes it suitable for precision electronics and high-temperature applications

- High Toughness: Tantalum wire has greater toughness than copper, making it suitable for environments requiring strength and resistance to fatigue

- Corrosion Resistance: It has strong resistance to a wide range of chemical substances, especially strong acids and alkalis

Applications

Tantalum wire has broad applications across several high-tech industries, including:

- Electronics Industry: Used in the production of capacitors, electrical components, and electron tubes

- Chemical Industry: Tantalum wire is used to fabricate reactors and piping systems in high-temperature and corrosive environments

- Aerospace: Tantalum wire is widely used in aerospace components, including heat shields, heating elements, and other high-temperature parts

- Military Equipment: Tantalum wire plays a crucial role in military equipment as key structural and electrical components

- Medical Devices: Due to its excellent biocompatibility, tantalum wire is also used in certain medical devices

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | Pb | |||||||||

| B | Ga | Bi | |||||||||

| F | Ge | Y | |||||||||

| Na | As | Th | |||||||||

| Mg | Se | Er | |||||||||

| Al | <5 | ppm | Zr | Ru | |||||||

| Si | 10 | ppm | Nb | 200 | ppm | Rh | |||||

| P | Mo | 20 | ppm | Os | |||||||

| Cl | Pd | Cd | |||||||||

| K | Ag | In | |||||||||

| Ca | Sn | ||||||||||

| Ti | <5 | ppm | Sb | ||||||||

| V | <5 | ppm | Ba | ||||||||

| Cr | ppm | Hf | 10 | ppm | |||||||

| Mn | Ta | Matrix | wt% | C | 15 | ppm | |||||

| Fe | 10 | ppm | W | 28 | ppm | S | |||||

| Co | Pt | O | 80 | ppm | |||||||

| Ni | <5 | ppm | Au | N | 20 | ppm | |||||

| Cu | Hg | H | 2 | ppm |

new material

new material