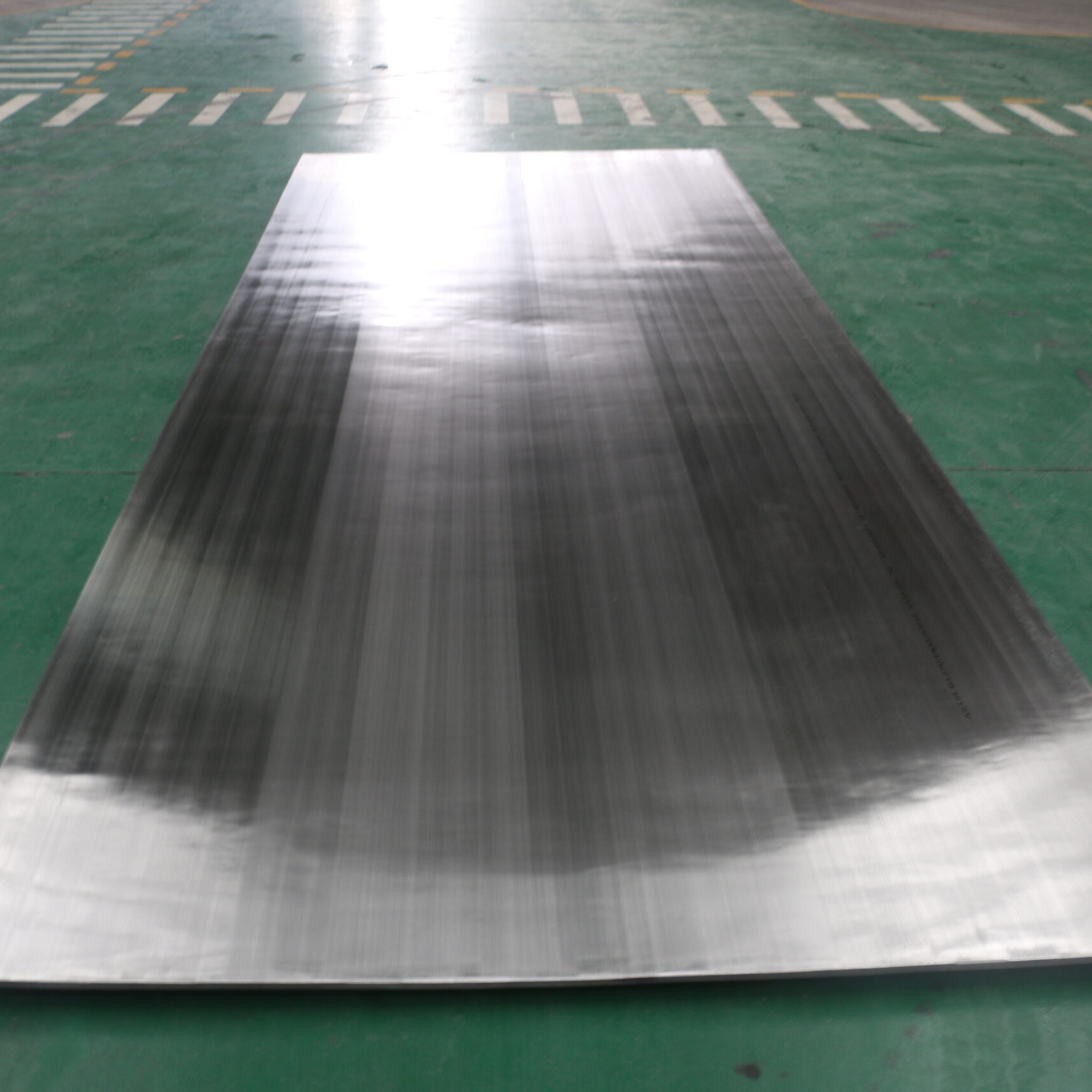

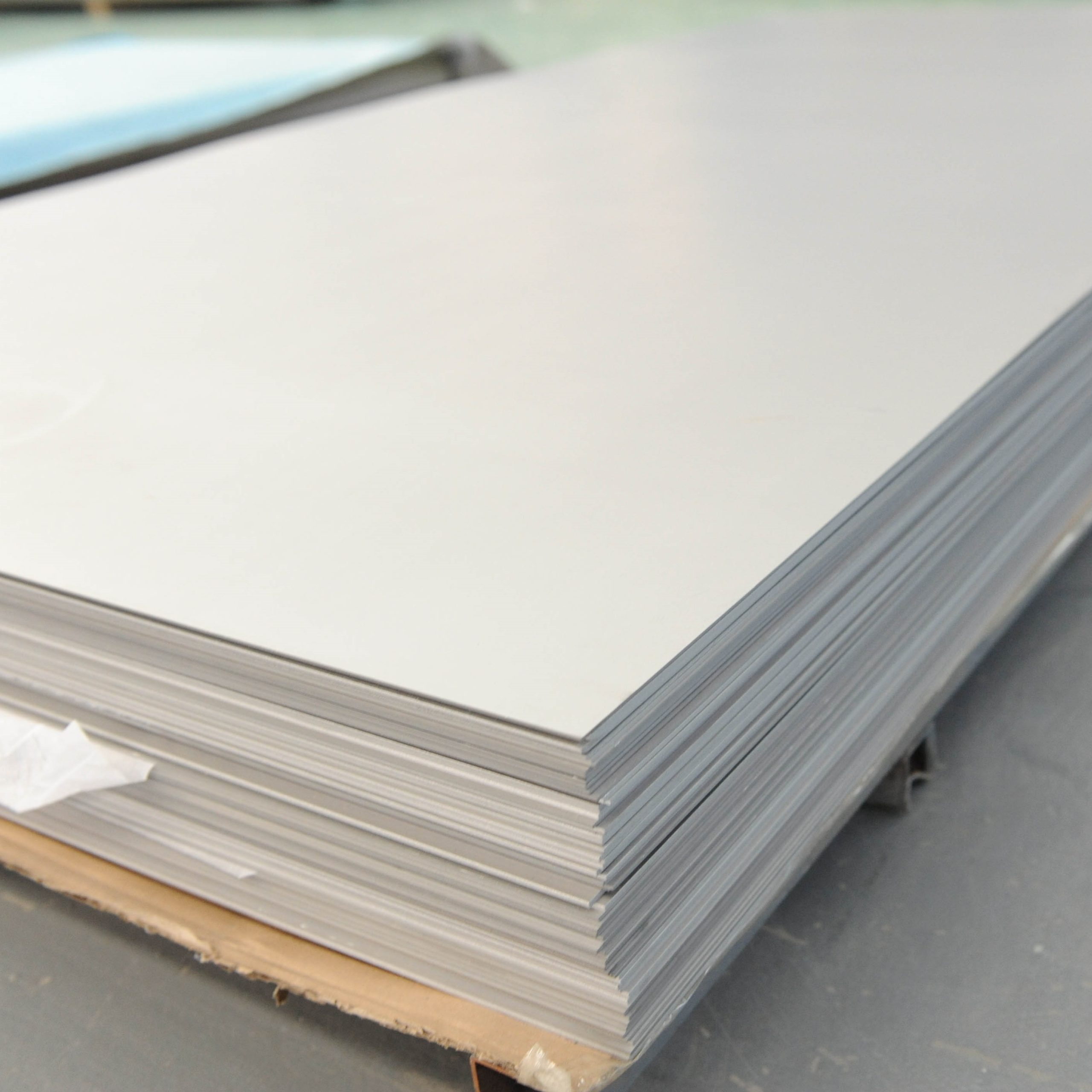

Product Overview

Titanium plates are made from high-purity titanium metal, offering excellent mechanical strength, corrosion resistance, and high-temperature performance. With a density of 4.506 g/cm³, a melting point of 1668°C, and a boiling point of 3287°C, titanium plates excel in extreme conditions. These properties make them ideal for use in aerospace, chemical, military, and other industries that require materials that can withstand high temperatures, corrosion, and high-strength demands.

Key Features

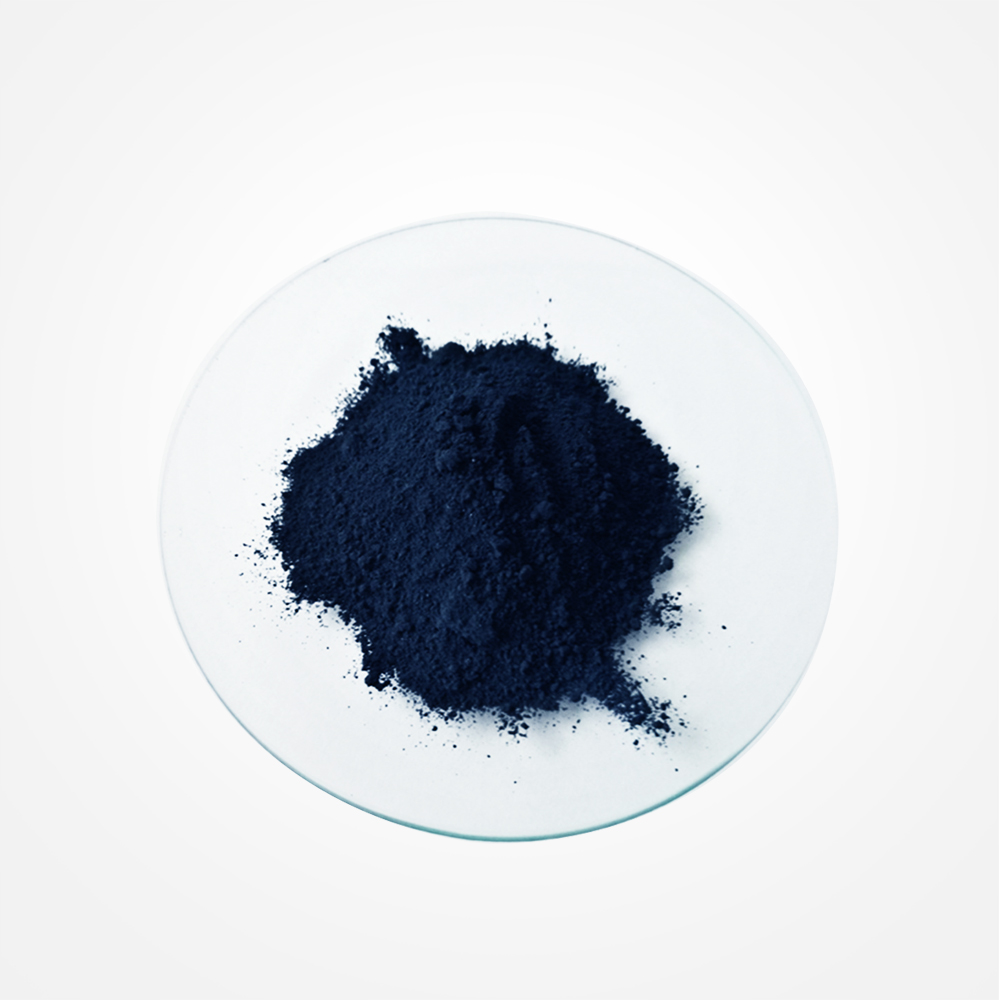

- High Purity: Made from high-purity titanium, ensuring superior physical and chemical performance.

- Excellent Corrosion Resistance: Titanium plates are highly resistant to corrosion from air, seawater, and various acidic and alkaline solutions.

- Strong High-Temperature Resistance: With a high melting point and boiling point, titanium plates maintain excellent performance in high-temperature environments.

- Lightweight and High Strength: Titanium has a high strength-to-weight ratio, making it ideal for applications requiring both strength and reduced weight.

- Good Machinability: Titanium plates can be customized to meet customer specifications and are suitable for precision machining and complex applications.

Applications

- Aerospace: Titanium plates are widely used in aircraft engine parts, rockets, and missile structures, providing high-strength and heat-resistant material support.

- Military: Titanium plates are used in military equipment such as high-pressure vessels, automatic rifles, and other weapon parts, meeting the durability needs in extreme conditions.

- Chemical and Petroleum: In the chemical and petroleum industries, titanium plates are used as corrosion-resistant materials in reactors, storage tanks, and pipelines.

- Medical: Titanium plates are commonly used in the medical field, especially for manufacturing prosthetics, orthopedic implants, and other products that require high biocompatibility.

- Other High-End Applications: Titanium plates are also used in high-pressure vessels, construction, automotive, electronics, and jewelry industries, offering excellent corrosion and mechanical properties.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | <0.005 | ppm | Zn | <1 | ppm | Pb | <1 | ppm | |||

| B | Ga | Bi | |||||||||

| F | Ge | Y | |||||||||

| Na | As | <1 | ppm | Th | |||||||

| Mg | <1 | ppm | Se | Er | |||||||

| Al | <2 | ppm | Zr | Ru | |||||||

| Si | <5 | ppm | Nb | Rh | |||||||

| P | Mo | <1 | ppm | Os | |||||||

| Cl | 0.06 | ppm | Pd | <5 | ppm | Cd | <1 | ppm | |||

| K | ppm | Ag | <0.02 | ppm | In | ||||||

| Ca | <1 | ppm | Sn | <5 | ppm | ||||||

| Ti | Matrix | wt% | Sb | <5 | ppm | ||||||

| V | Ba | <1 | ppm | ||||||||

| Cr | 2.7 | ppm | Hf | ||||||||

| Mn | <1 | ppm | Ta | C | |||||||

| Fe | <2 | ppm | W | S | |||||||

| Co | <1 | ppm | Pt | O | |||||||

| Ni | <2 | ppm | Au | N | |||||||

| Cu | <2 | ppm | Hg | H |

new material

new material