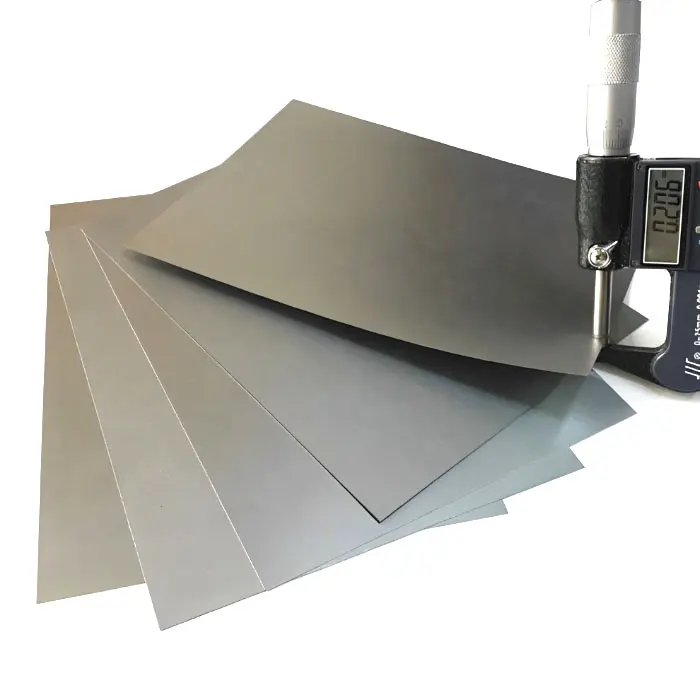

Product Overview

High purity niobium sheets are high-performance metal materials widely used in fields that demand exceptional strength, corrosion resistance, and high-temperature stability. Due to their superior physical properties, niobium sheets are commonly employed in research, nuclear industries, and the manufacture of special alloys, providing stable support even in harsh environments.

Features

- High Purity:Ensures excellent chemical stability and long-term reliability in harsh environments.

- High Temperature Resistance:Melting point up to 2468°C, ideal for high-temperature applications.

- Good Ductility and Machinability:Can be easily processed and shaped for various applications.

- Outstanding Corrosion Resistance:Excellent resistance to a wide range of chemical substances.

- Good Thermal and Electrical Conductivity:Efficient in heat and electrical flow applications.

- Cost-Effective Alternative to Tantalum:Shares similar chemical properties with tantalum but at a lower cost.

Applications

- Nuclear Industry:Niobium sheets are widely used in nuclear reactors, benefiting from their low thermal neutron absorption.

- Superconducting Applications:Essential in superconducting materials, commonly used in high-energy physics research.

- High-Temperature Alloys:Used to manufacture high-temperature alloys, widely applied in aerospace and energy industries.

- Chemical Industry:Suitable for chemical reaction vessels and equipment due to its superior corrosion resistance.

- Electroceramics and Electrical Equipment:Used in electroceramic components and high-voltage equipment due to its excellent electrical properties.

- Medical Applications:Niobium’s biocompatibility makes it ideal for use in medical devices.

- Lighting Industry:Niobium (doped with zirconium) is used in high-pressure sodium lamp arc tube sealing materials.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | Pb | |||||||||

| B | Ga | Bi | |||||||||

| F | Ge | Y | |||||||||

| Na | As | Th | |||||||||

| Mg | Se | Er | |||||||||

| Al | Zr | <10 | ppm | Ru | |||||||

| Si | <5 | ppm | Nb | Matrix | wt% | Rh | |||||

| P | Mo | <10 | ppm | Os | |||||||

| Cl | Pd | Cd | |||||||||

| K | Ag | In | |||||||||

| Ca | Sn | ||||||||||

| Ti | <5 | ppm | Sb | ||||||||

| V | Ba | ||||||||||

| Cr | <10 | ppm | Hf | ||||||||

| Mn | Ta | 42 | ppm | C | 29 | ppm | |||||

| Fe | 10 | ppm | W | 20 | ppm | S | |||||

| Co | Pt | O | 100 | ppm | |||||||

| Ni | <10 | ppm | Au | N | 10 | ppm | |||||

| Cu | Hg | H | 10 | ppm |

new material

new material