Zirconia ceramic components for textile machinery offer exceptional wear resistance, optimized mechanical strength, and superior thermal stability. Designed for high-precision textile manufacturing, they ensure extended durability, reduced friction, and reliable operational efficiency.

Product Overview:

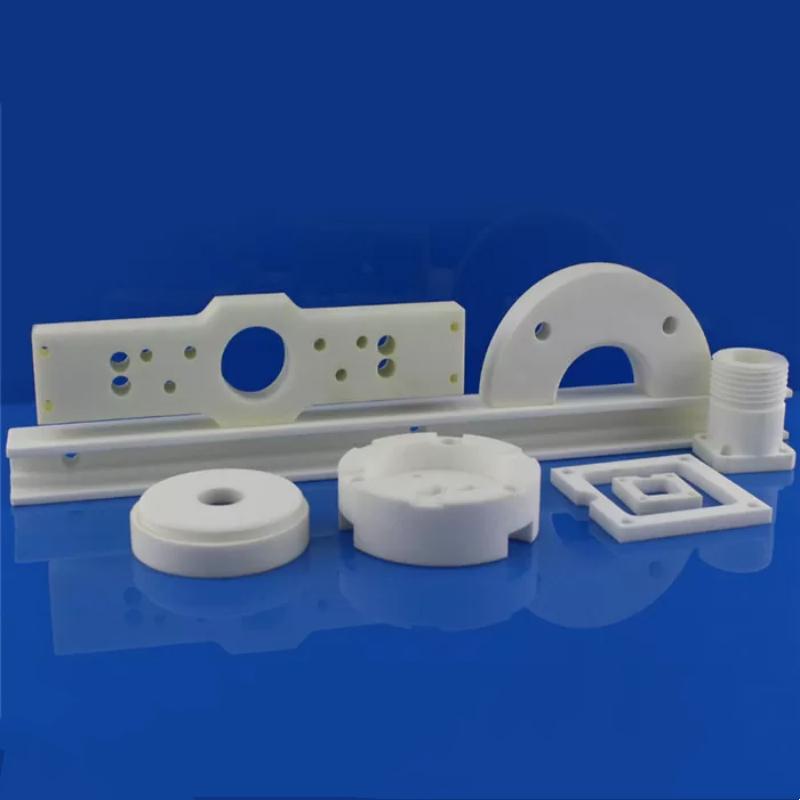

Zirconia Ceramic Components for Textile Machinery, commonly referred to as wear-resistant ceramic thread guide channels or corner protectors, are high-performance ceramic parts designed specifically for textile machinery. These components are used in the textile production process to guide and protect fibers. Their superior wear resistance and friction-reducing properties help minimize fiber wear and improve the quality of textile processing. The smooth surface of zirconia ceramic effectively reduces friction between the fibers and machinery, which extends the life of both the fibers and mechanical components.

Product Features:

- Outstanding Wear Resistance and Fracture Strength:Zirconia ceramics have a Vickers hardness of up to 1175 Kg/mm², making them highly resistant to wear and impact, ensuring that fibers are not damaged during processing.

- Chemical Stability:Zirconia ceramics exhibit excellent chemical resistance, making them ideal for environments where exposure to corrosive substances is common in the textile industry.

- High Precision Manufacturing:Manufactured using precision techniques such as laser cutting, these components meet stringent industrial standards, ensuring that every detail of the thread guide channels and protective sleeves is accurate.

- Smooth Surface Treatment:The high smoothness of the ceramic surface reduces friction, improves textile quality, and effectively prevents fiber breakage.

- Custom Designs and Sizes:Components can be tailored to specific requirements, including different shapes and sizes, to ensure perfect compatibility with various machinery structures.

Applications:

- Textile Machinery:Used as thread guides and protective components such as thread guide channels and corner protectors, reducing fiber wear during the textile production process and improving production efficiency and product quality.

- Industrial Automation:Used in automated equipment for precise fiber handling and guiding, optimizing the accuracy and efficiency of production processes.

- Medical Devices:Suitable for use in medical equipment where non-contamination and corrosion resistance are critical, protecting sensitive components from mechanical wear.

- Electronic Manufacturing:Used as insulators and structural supports in the electronics industry to manage thermal and mechanical stresses, offering additional protection to sensitive electronic components.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform