Silicon nitride nanoparticles (Si₃N₄) provide optimized thermal stability, superior mechanical strength, and enhanced wear resistance. Designed for high-performance ceramic coatings and electronic applications, they ensure efficient heat dissipation, extended durability, and high adaptability.

Product Overview

Silicon nitride nanoparticles (Si₃N₄) are composed of silicon and nitrogen elements, offering excellent physical properties due to their strong chemical bonds. Known for their high hardness, resistance to high temperatures, thermal shock resistance, and corrosion resistance, silicon nitride is widely used in high-performance ceramic materials. It excels in environments with high demands for wear resistance, heat dissipation, and mechanical strength. Common crystal forms of silicon nitride include α-Si₃N₄, β-Si₃N₄, and γ-Si₃N₄.

Key Features

- High Hardness and Wear Resistance: Silicon nitride nanoparticles exhibit extreme hardness and wear resistance, making them ideal for ceramic coatings on metal surfaces.

- High Temperature and Thermal Shock Resistance: The material maintains stability under high temperatures and fluctuating temperature conditions, offering exceptional thermal shock resistance.

- Corrosion and Radiation Resistance: Superior corrosion resistance and radiation stability make Si₃N₄ ideal for specialized industrial applications.

- Low Friction Coefficient: As a self-lubricating material, it significantly enhances the lifespan of mechanical components.

- High Thermal Conductivity: With excellent heat transfer properties, silicon nitride is a great choice for electronic device heat dissipation.

Applications

- Wear-resistant Coatings: Used to improve the wear resistance and component lifespan of ceramic-metal composite coatings.

- Electronic Device Heat Dissipation: As a heat management material, silicon nitride is commonly used in semiconductor ceramic substrates.

- Composite Material Reinforcement: Used as a filler to reinforce polymer matrices, enhancing mechanical properties and thermal conductivity of composites.

- Bonding and Sealing Materials: Applied in modified materials to improve mechanical strength and durability.

- Coating Additives: Enhances the wear resistance and solvent resistance of coatings.

| Parameter | Description |

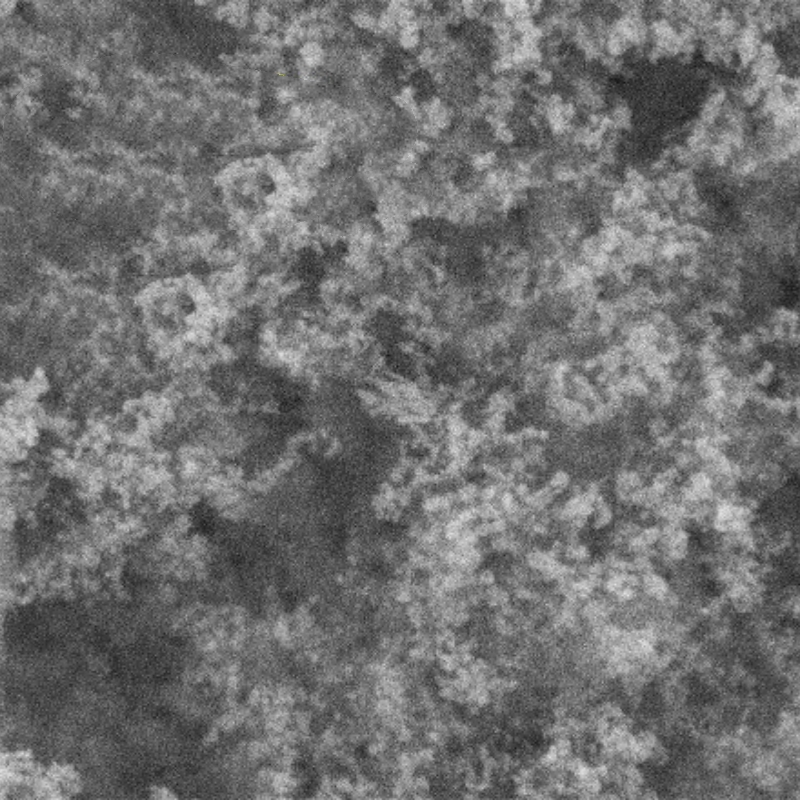

| Size | 20-50 nm (SEM) |

| Appearance | White powder |

| Purity | ~70 wt% (EDS) |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform