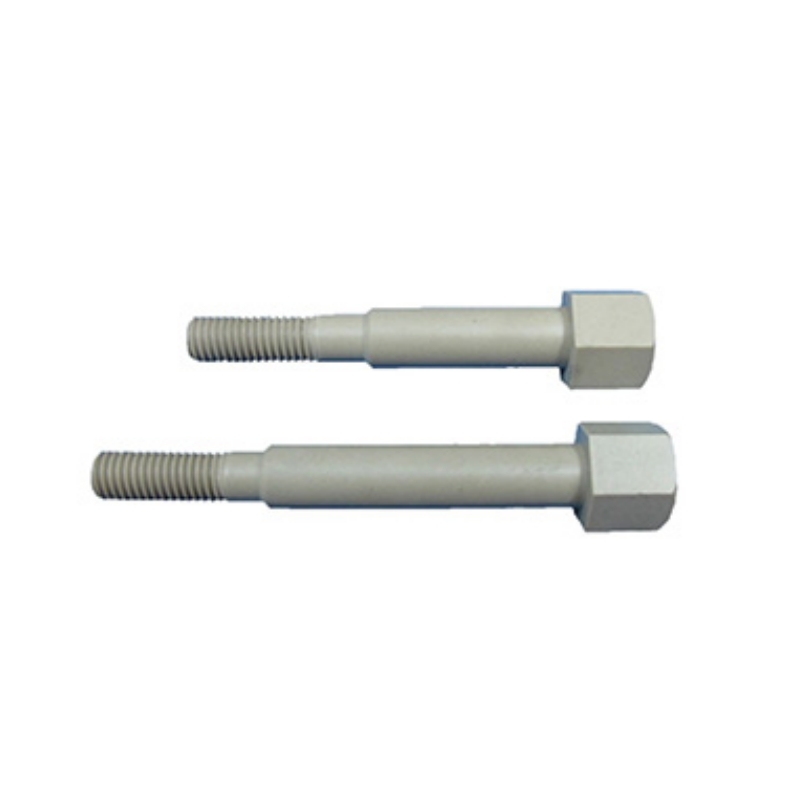

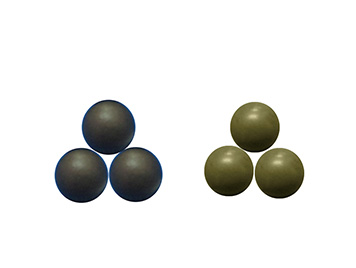

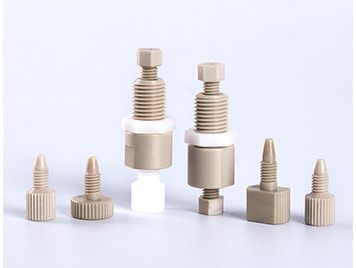

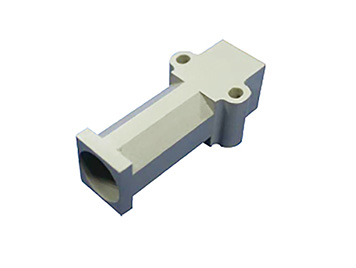

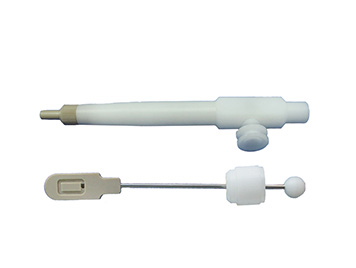

PEEK Parts (Polyetheretherketone) are high-performance polymer components designed for extreme mechanical strength, thermal resistance, and chemical stability. They are widely used in aerospace, medical, automotive, and industrial applications requiring precision, durability, and reliability.

Product Overview

PEEK parts are manufactured from high-performance polyetheretherketone (PEEK) material, offering excellent properties including high temperature resistance, chemical corrosion resistance, high-pressure tolerance, and mechanical strength. The long-term operating temperature of PEEK parts is around 260-280°C, with short-term use capable of reaching up to 330°C, and they can withstand pressures up to 30MPa. This makes them ideal for use in environments with extreme conditions requiring high temperature, corrosion resistance, and pressure tolerance. In addition to these characteristics, PEEK parts also have good self-lubricating properties, excellent machinability, and stable electrical insulation, making them suitable for a variety of applications in aerospace, automotive manufacturing, electronics, medical, and food processing industries.

Key Features

- Excellent High-Temperature Resistance: PEEK material can withstand prolonged exposure to high temperatures, making it suitable for applications like sealing and insulation in high-temperature environments.

- Chemical Stability: It offers exceptional resistance to a wide range of chemicals, ensuring stable performance in harsh chemical environments.

- Self-Lubricating Properties: PEEK has inherent self-lubricating properties, reducing friction and wear, thereby extending the lifespan of the parts.

- High Pressure Resistance: PEEK parts can withstand up to 30MPa of pressure, making them ideal for high-pressure applications.

- Good Electrical Insulation: PEEK exhibits stable electrical insulation performance, suitable for electrical equipment and components.

- Ease of Machinability: PEEK material is easy to process into various shapes, meeting the diverse needs of customers.

- Hydrolysis Resistance: PEEK has excellent resistance to hydrolysis, maintaining stable performance even in humid environments.

Applications

- Aerospace: PEEK parts are used in the aerospace industry for sealing, insulation, and other critical components in high-temperature and high-pressure environments.

- Automotive Manufacturing: They are widely used in the automotive industry for high-temperature seals, wear-resistant parts, offering durability and reliability.

- Electronics & Electrical: PEEK parts are extensively applied in the electronics and electrical industries, used for electrical insulation, sensors, and other components.

- Medical: Due to its non-toxicity and biocompatibility, PEEK parts are commonly used in medical devices, implants, and other healthcare applications.

- Food Processing: In food processing, PEEK parts are used in equipment exposed to high temperatures and chemical corrosion, ensuring product safety and long service life.

- Petrochemical: PEEK parts are widely used in the petrochemical industry for seals, corrosion-resistant components, and other critical applications.

- Military & Nuclear Energy: PEEK’s excellent performance makes it a popular material for high-temperature and high-pressure applications in the military and nuclear energy sectors.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform