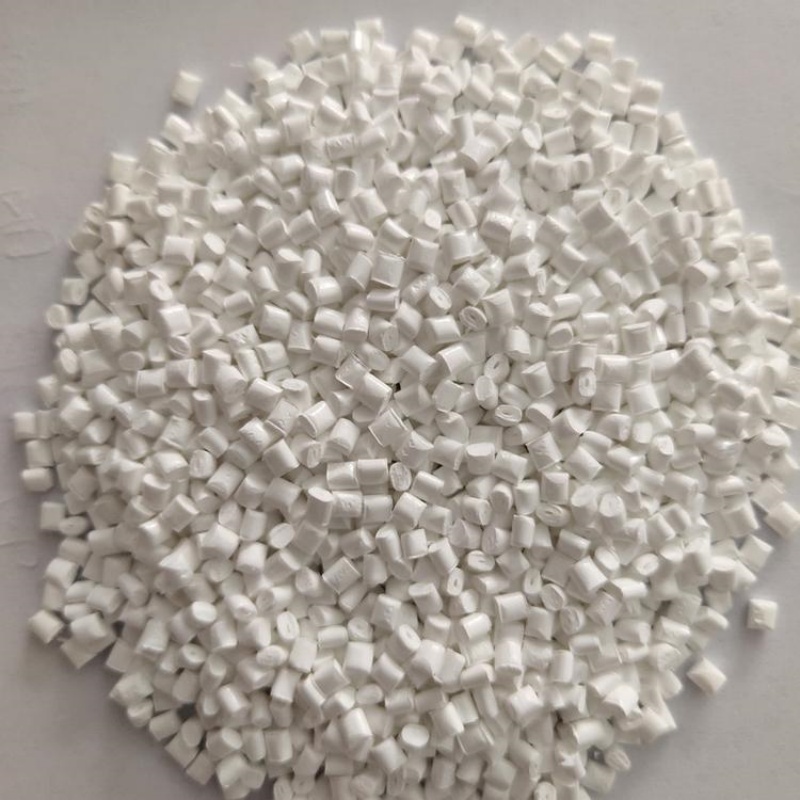

PA66 Unfilled (Unfilled Polyamide 66) provides balanced mechanical properties, excellent thermal stability, and good processability. Designed for general engineering applications, it offers high toughness, chemical resistance, and reliable durability.

Product Overview

PA66 Unfilled is a polyamide 66 (Nylon 66) material without any fillers. It offers good internal lubrication, excellent mold release properties, and a short molding cycle. This material is especially suitable for applications requiring high flowability and ease of molding, making it ideal for producing complex-shaped components.

Key Features

- Internal Lubrication: The material has inherent lubricating properties that reduce friction during processing, improving the smoothness of the molding process.

- Excellent Mold Release: The material’s superior mold release makes it easier to remove parts from molds, helping to reduce production time and costs.

- Short Molding Cycle: It offers a shorter molding cycle, enhancing production efficiency.

- High Mechanical Strength: Provides good mechanical performance, making it suitable for high-load applications.

Applications

- Cable Ties: Ideal for the production of cable ties, offering durability and ease of processing.

- Clips: Used to manufacture various types of clips, providing good mechanical strength and long service life.

- Coil Frames: Suitable for producing coil frame components, providing excellent physical stability.

- Antennas: Used in the manufacture of antenna components, offering good formability and mechanical strength.

- Wire Harnesses: Ideal for making components for electrical wire harnesses, ensuring durability and high performance.

| Test Properties | Unit | Test Method | Test Condition | Typical Value |

| Test Standards | ISO, UL, IEC, ASTM | |||

| Sample Handling | 23℃, 24h | |||

| Environment | 23℃, 50%RH | |||

| Physical Properties | ||||

| Density | g/cm³ | ISO 1183 | 1.14 | |

| Filler Content | % | ISO 1172 | - | |

| Mold Shrinkage | % | ISO 294 | Parallel: 1.3%, Vertical: 1.8% | |

| Mechanical Properties | ||||

| Tensile Strength | MPa | ISO 527 | Type I sample, 50mm/min | 78 |

| Elongation at Break | % | ISO 527 | Type I sample, 50mm/min, Gauge length 50mm | 20 |

| Flexural Strength | MPa | ISO 178 | 23℃, 10mm/min | 90 |

| Flexural Modulus | MPa | ISO 178 | 23℃, 10mm/min | 2900 |

| Izod Impact Strength (Notched) | KJ/m² | ISO 180 | 23℃ | 4 |

| Charpy Impact Strength (Unnotched) | KJ/m² | ISO 179 | 23℃ | NB |

| Thermal Properties | ||||

| Melting Point | ℃ | ISO 11357-1 | 260 | |

| Heat Deflection Temperature (HDT) | ℃ | ISO 75 | 0.45MPa: 210℃, 1.8MPa: 70℃ | |

| Flammability | ||||

| UL Flammability Class | UL-94 | HB | ||

| Glow Wire Ignition Temperature (GWIT) | ℃ | IEC 60695-2-13 | - | |

| Electrical Properties | ||||

| Surface Resistivity | Ω | IEC60093 | 100000000000000 | |

| Volume Resistivity | Ω·cm | IEC60093 | 1000000000000000 |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform