Natural gas hydrogenation catalyst is a high-performance catalytic material designed for the selective hydrogenation of natural gas impurities, ensuring enhanced fuel quality and optimized reaction efficiency. Engineered using advanced metal-supported formulations, it enables superior hydrogen absorption, improved conversion rates, and extended operational stability for industrial applications. This catalyst is widely used in fuel processing, petrochemical refining, and hydrocarbon upgrading, delivering reliable performance in controlled hydrogenation environments.

Product Overview:

The NG-210 hydrogenation catalyst is specifically designed for natural gas hydrogenation reactions. It features cobalt and molybdenum as the main active components, offering exceptional hydrogenation activity and good mechanical strength. This catalyst has been successfully used in natural gas processing plants worldwide and is widely used in hydrogenation treatments to effectively remove harmful impurities and improve natural gas quality.

Key Features:

- Excellent Hydrogenation Activity:Increases the efficiency of hydrogenation reactions, ideal for natural gas hydrogenation treatment.

- High Strength:High compressive strength, enhancing the catalyst's stability and service life.

- Low Sulfur Removal Capability:Effectively removes sulfur compounds from natural gas, reducing sulfur content to below 0.1 ppm.

- Proven Global Use:Successfully applied in multiple hydrogenation units worldwide.

Applications:

- Natural Gas Hydrogenation Treatment:Used for desulfurization and hydrogenation refining of natural gas to enhance its quality.

- Petrochemical Industry:Applied in the hydrogenation refining process for natural gas in petrochemical production.

- Clean Energy:Supports the use of natural gas as a clean energy source by removing harmful components like sulfur.

| Physical and Chemical Properties | |

| Item | Specification |

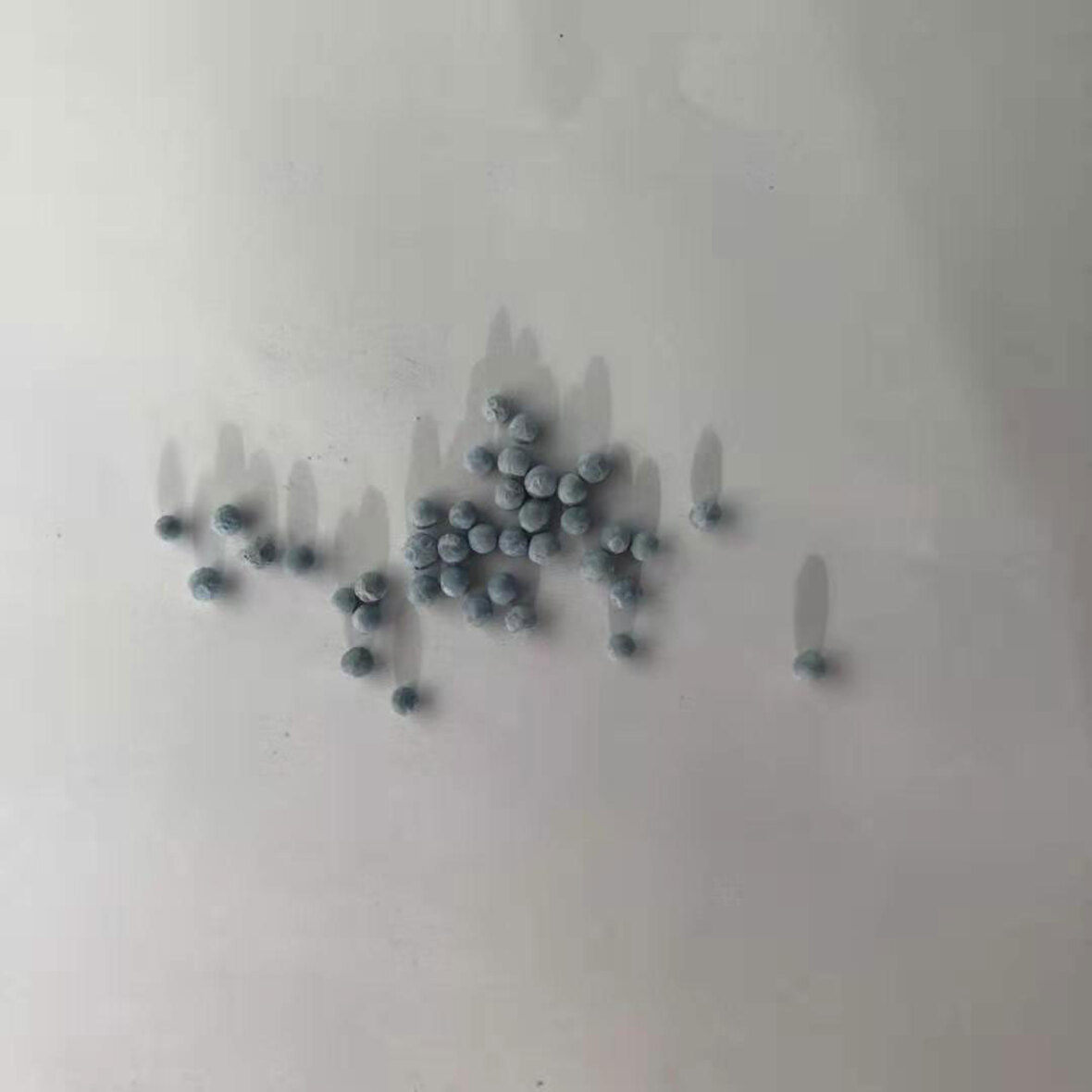

| Appearance | Spherical |

| Specifications | 2-4 mm |

| Bulk Density | 600-700 kg/m³ |

| Cobalt Oxide (CoO) Content | ≥2.0% |

| Molybdenum Trioxide (MoO₃) Content | ≥10% |

| Crushing Strength | ≥80 N/particle |

| Item | Specification |

| Temperature | 300-350 ℃ |

| Space Velocity | 400 hr⁻¹ |

| Pressure | ≥10.0 kg/cm² g |

| Sulfur Content | ≤0.1 ppm |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform