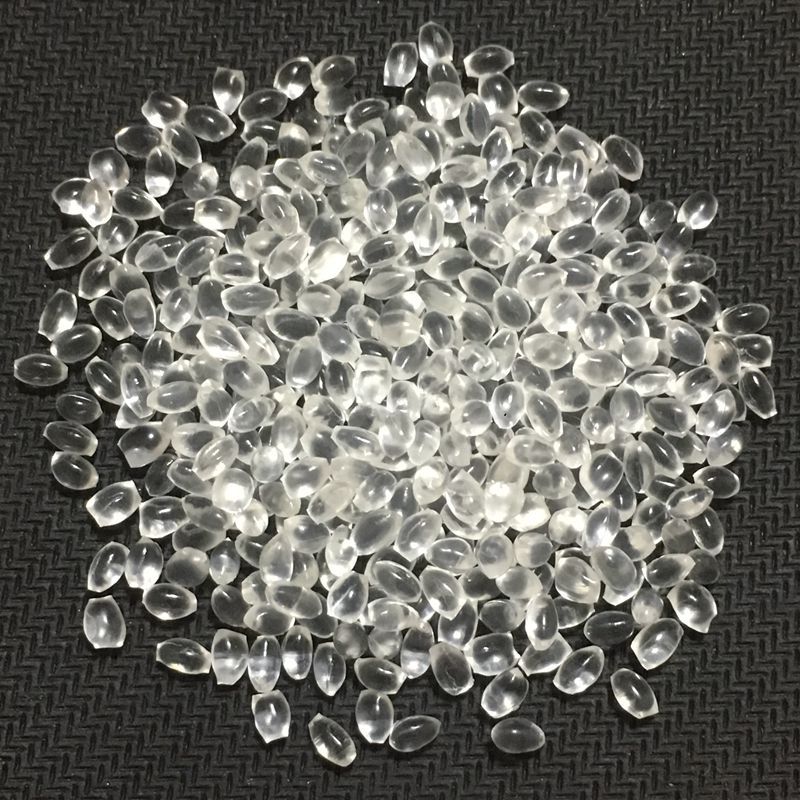

Glass Fiber Reinforced AS Material offers enhanced mechanical strength, superior rigidity, and excellent thermal resistance. Designed for automotive, electrical, and industrial applications, it ensures durability, dimensional stability, and long-term reliability.

Product Overview

Glass fiber reinforced AS (Polyphenylene Sulfide) material significantly enhances the rigidity, dimensional stability, and processing performance of the base polymer. This composite material offers excellent thermal stability, mechanical strength, and corrosion resistance, making it ideal for various industrial applications, particularly in fields that demand high strength and stability.

Key Features

- High Rigidity: The incorporation of glass fiber improves the material’s rigidity, enabling it to maintain shape stability under heavy loads.

- Excellent Dimensional Stability: Suitable for use in high-temperature or humid environments, this material effectively reduces deformation, ensuring long-term stability of the product.

- Good Processability: The material is easy to process and is compatible with common processing techniques such as injection molding, offering good moldability.

- High Temperature and Corrosion Resistance: The material provides excellent heat resistance and chemical corrosion resistance, making it suitable for use in complex environments.

Applications

Glass fiber reinforced AS material is widely used in the following fields:

- Automotive: Used in the manufacture of automotive components, particularly interior and exterior trim parts that require high strength and dimensional stability.

- Air Conditioning: Applied in air conditioning system components, such as radiators and casings, where good heat resistance and corrosion resistance are crucial.

- Electronics: Suitable for the housing, connectors, and other components of electronic devices, providing good structural strength and electrical insulation.

- Sports and Recreation Equipment: Widely used in high-strength sports and recreational equipment, offering excellent toughness and impact resistance.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform