Denitration and dust removal integrated ceramic membranes and equipment provide high-efficiency pollutant filtration, optimized chemical resistance, and superior durability. Designed for industrial air purification, they ensure reliable emissions control, extended lifespan, and sustainable environmental protection.

Product Overview

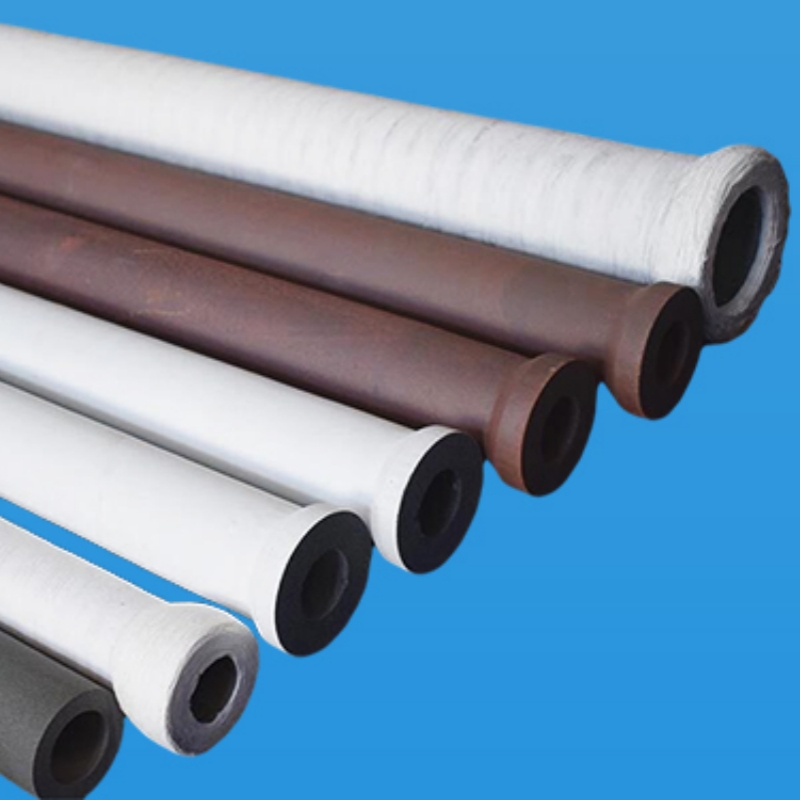

The Denitration and Dust Removal Integrated Ceramic Membrane is an innovative ceramic membrane material designed for both efficient dust removal and denitration. Its unique design incorporates high-efficiency denitration catalysts within the pore structure of the ceramic membrane. This allows it to first effectively remove particulate matter from flue gas in high-temperature environments (200-420°C) and then, with the catalyst and added NH3, convert NOx in the flue gas into harmless substances, achieving ultra-low emissions. This product offers exceptionally high denitration efficiency and excellent dust removal performance, making it widely applicable in various industrial flue gas treatment systems.

Features

- Dual Function for Dust Removal and Denitration: Simultaneously removes particulate matter and harmful NOx gases from flue gas, achieving "dual purification."

- Ultra-Low Emissions: Denitration efficiency can reach over 80%, with dust emissions ≤ 10mg/m³, meeting ultra-low emission standards.

- High Temperature Adaptability: Stable operation in high-temperature environments ranging from 200°C to 420°C, suitable for various high-temperature flue gas treatment needs.

- Long Durability: Ceramic membrane material offers a long service life with strong anti-fouling capabilities and low maintenance costs.

- Efficient Catalytic Reaction: The multi-dimensional pore structure of the membrane combined with the catalyst enhances NOx conversion efficiency, reducing harmful gas emissions.

Applications

- Industrial Flue Gas Treatment: Widely used in flue gas denitration and dust removal systems in industries such as steel, cement, power generation, and chemicals.

- Ultra-Low Emission Control: Helps meet increasingly stringent environmental emission standards, assisting companies in achieving ultra-low emission requirements.

- Environmental Protection: Plays a crucial role in reducing harmful gas emissions in industrial exhaust treatment, contributing significantly to improving air quality and environmental protection.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform