Cobalt lumps are high-purity materials used in various industrial applications, including aerospace engineering, electronics, and battery manufacturing. They are known for their excellent corrosion resistance, high melting point, and unique properties.

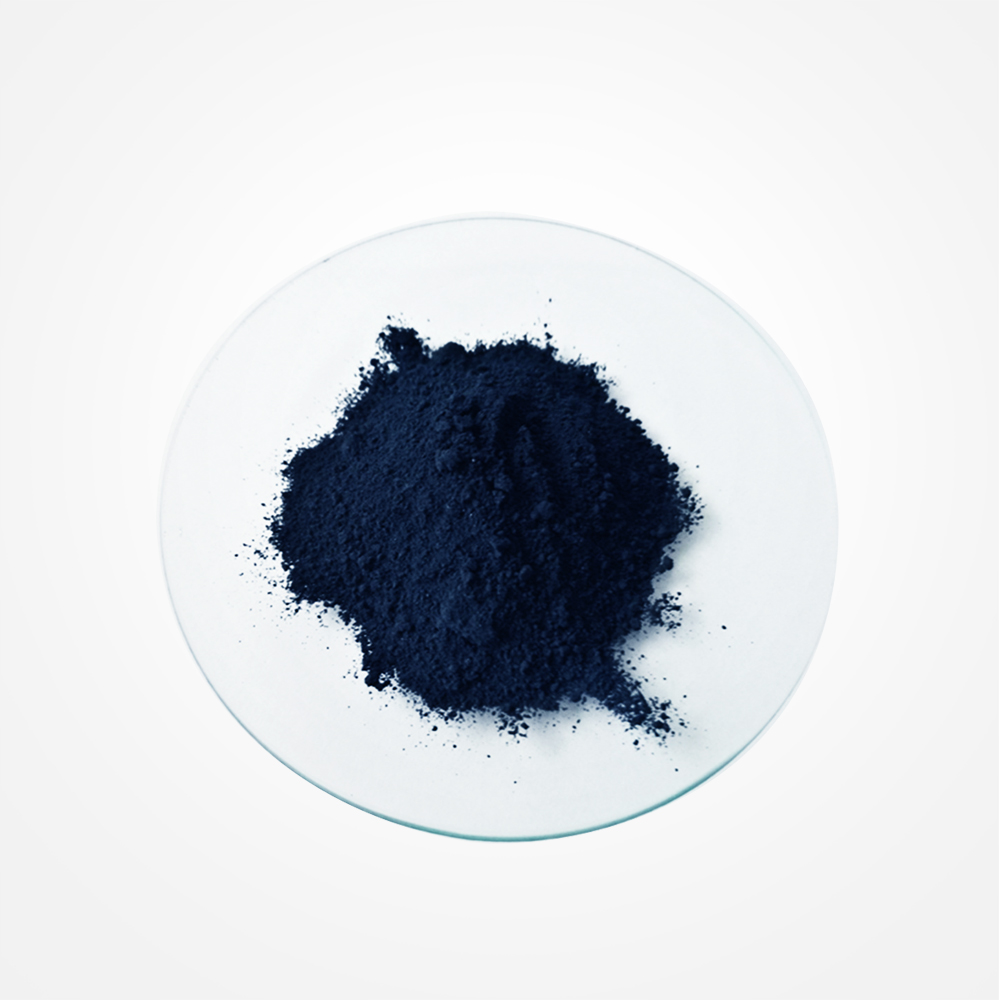

Product Overview:

Cobalt lumps are silver-white metallic blocks that possess ferromagnetic properties, excellent ductility, and resistance to high temperatures and corrosion. With a melting point of approximately 1495°C, a boiling point of about 2870°C, and a density of 8.9 g/cm³, these characteristics make cobalt lumps widely applicable in mechanical manufacturing and high-tech industries.

Features:

- High Purity:Achieving 4N (99.99%) purity ensures superior material performance.

- Excellent Physical Properties:Offers good ductility and resistance to high temperatures and corrosion.

- Customizable Options:Available in various sizes to meet different customer requirements.

Applications:

- Industrial Alloys:Used in the manufacture of super heat-resistant alloys, widely applicable in aerospace, gas turbines, and other high-temperature component environments.

- Battery Industry:Serves as a cathode material in lithium-ion batteries (e.g., lithium cobalt oxide), enhancing energy density and cycle performance; also utilized in Ni/Co secondary alkaline batteries.

- Catalysts:Acts as a catalyst in the chemical industry, participating in hydrogenation, dehydrogenation reactions, and ammonia synthesis in petrochemical production.

- Ceramics and Glass Industry:Employed as a coloring agent in ceramic glazes and glass to add specific colors and luster.

- Other Applications:Used in pigments, rubber, adhesives, and can also be applied in radiotherapy and industrial flaw detection.

| Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit | Element | Measured Value | Standard Value | Unit |

| Li | Zn | 10 | ppm | Pb | <10 | ppm | |||||

| B | Ga | Bi | <10 | ppm | |||||||

| F | Ge | Y | |||||||||

| Na | As | Th | |||||||||

| Mg | <10 | ppm | Se | Er | |||||||

| Al | <10 | ppm | Zr | <10 | ppm | Ru | |||||

| Si | Nb | Rh | |||||||||

| P | Mo | <10 | ppm | Os | |||||||

| Cl | Pd | Cd | |||||||||

| K | Ag | In | |||||||||

| Ca | Sn | ||||||||||

| Ti | 10 | ppm | Sb | <10 | ppm | ||||||

| V | Ba | ||||||||||

| Cr | 18 | ppm | Hf | <10 | ppm | ||||||

| Mn | <10 | ppm | Ta | C | |||||||

| Fe | 43 | ppm | W | <20 | ppm | S | |||||

| Co | Matrix | wt% | Pt | O | |||||||

| Ni | 95 | ppm | Au | N | |||||||

| Cu | 135 | ppm | Hg | H |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform