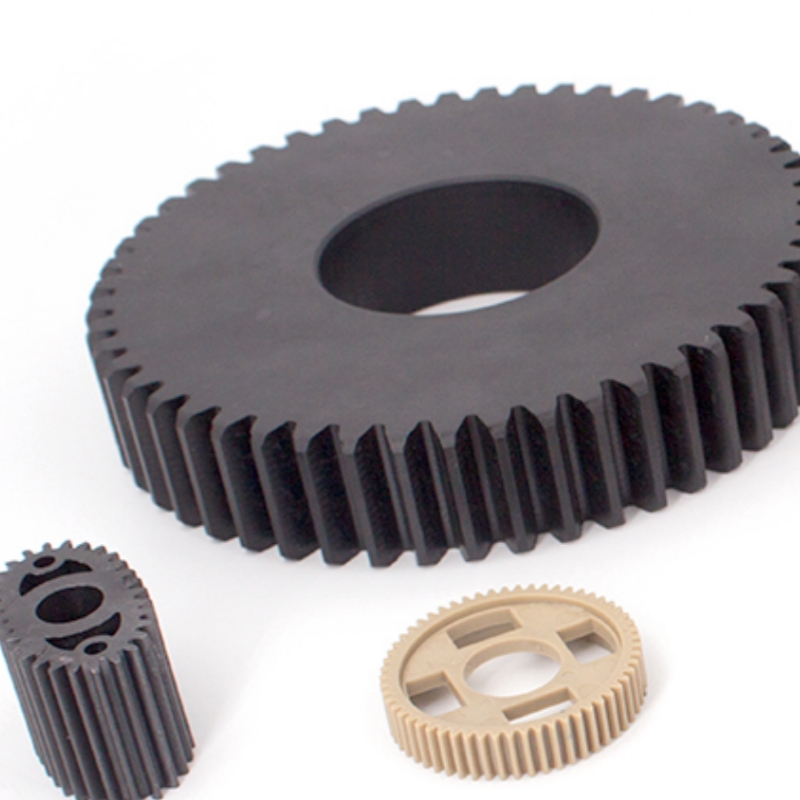

PEEK Gears (Polyetheretherketone) are high-performance engineering components known for their exceptional wear resistance, mechanical strength, and thermal stability. They are widely used in aerospace, automotive, medical, and industrial applications requiring precision, durability, and chemical resistance.

Product Overview

PEEK gears are made from high-performance PEEK material, offering excellent mechanical properties and chemical stability, suitable for demanding high-temperature, high-pressure, and corrosive environments. The lightweight, low-friction, and high-wear-resistance characteristics of PEEK gears ensure stability and durability during high-load operations. Additionally, PEEK gears help reduce noise and inertia torque, and provide exceptional resistance to oils and fuels, making them ideal for use across various industrial sectors.

Key Features

- Noise Reduction, Low Density, Lightweight: PEEK gears have low density and noise-reducing properties, maintaining quiet operation even under high loads.

- Reduced Inertia Torque: Due to the low density, the inertia torque of PEEK gears is lower, enhancing system response speed and efficiency.

- Strong Chemical Corrosion Resistance: PEEK gears effectively resist acids, alkalis, salts, and a variety of chemicals, ensuring long-term stable operation.

- Excellent Oil and Fuel Resistance: Particularly suitable for environments exposed to petroleum, automotive fuels, and lubricating oils.

- Low Moisture Absorption, No Expansion: PEEK gears exhibit extremely low moisture absorption, maintaining stable performance in humid environments without expansion.

- High Wear Resistance: Exceptional wear resistance extends the lifespan of the gears.

- Good Compatibility with Metals and Other Plastics: PEEK gears have good compatibility with metals and other materials, making them suitable for various combinations in applications.

- Injection Molding: PEEK gears can be molded through injection molding, reducing production costs.

Applications

- Automotive Manufacturing: PEEK gears are widely used in the automotive industry, especially in transmission systems and engine components, due to their excellent heat resistance and corrosion resistance.

- Aerospace: In aerospace, PEEK gears are used in high-temperature, corrosive, and high-pressure environments, benefiting from their self-lubricating properties and durability in precision components.

- Electronics and Electrical: PEEK gears, with their insulating properties, are suitable for various electrical devices, providing excellent electrical performance and mechanical strength.

- Medical Equipment: PEEK gears are used in medical devices, particularly in environments with high temperatures and chemical exposure.

- Food Processing: Compliant with FDA standards, PEEK gears can be used in the food processing industry, ensuring sanitary conditions while enhancing mechanical performance.

- Petrochemical: In the petrochemical industry, PEEK gears excel in harsh chemical environments, offering superior chemical resistance and high-temperature performance.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform