Nano transparent functional masterbatch provides optimized optical clarity, superior mechanical reinforcement, and enhanced compatibility with polymer matrices. Designed for advanced film and injection molding applications, it ensures uniform dispersion, extended durability, and high adaptability.

Product Overview

Nano Transparent Functional Masterbatch is synthesized using advanced nanotechnology, incorporating inorganic materials with particle sizes of less than 100 nanometers. This masterbatch significantly enhances the transparency and gloss of plastic products while maintaining excellent dispersion and chemical stability. It improves the gloss and color of the product without compromising its transparency, making it widely applicable in the processing of various plastic products, especially in the extrusion and injection molding of polyolefins such as polyethylene (PE) and polypropylene (PP).

Key Features

- High Transparency: With particle sizes smaller than 100 nanometers, this masterbatch maintains a high light transmittance. When added in quantities of 10-45%, it does not affect the transparency of the final product.

- High Gloss: The inorganic nano-particles in the masterbatch result in finished products with ultra-high gloss, enhancing their visual appeal.

- Bright Color: The product achieves a high L value of 99.5, significantly improving the color intensity of the product and making it brighter and more vivid.

- Good Dispersion: Utilizing new nanotechnology for organic coating, this masterbatch ensures excellent compatibility and dispersibility with resins, ensuring easy blending during processing.

- Excellent Chemical Resistance: The inorganic materials used in the masterbatch offer good resistance to acids, alkalis, and various chemicals, ensuring product stability in diverse environments.

- Non-toxic and Safe: SGS certified, the product is free from heavy metals and harmful substances, with low impurity content and high purity, ensuring safety and surface cleanliness of the final product.

Applications

- Polyolefin Materials: Widely used in the extrusion, injection molding, and blow molding of LLDPE, LDPE, HDPE, PP, and other polyolefins, enhancing product transparency and gloss.

- Biodegradable Plastics: Suitable for processing biodegradable plastics, improving their appearance and performance.

- Other Plastic Products: Can also be applied to other polyolefin-based materials and various plastic processing methods, improving the visual effects and durability of the final products.

| Technical Parameter | Description |

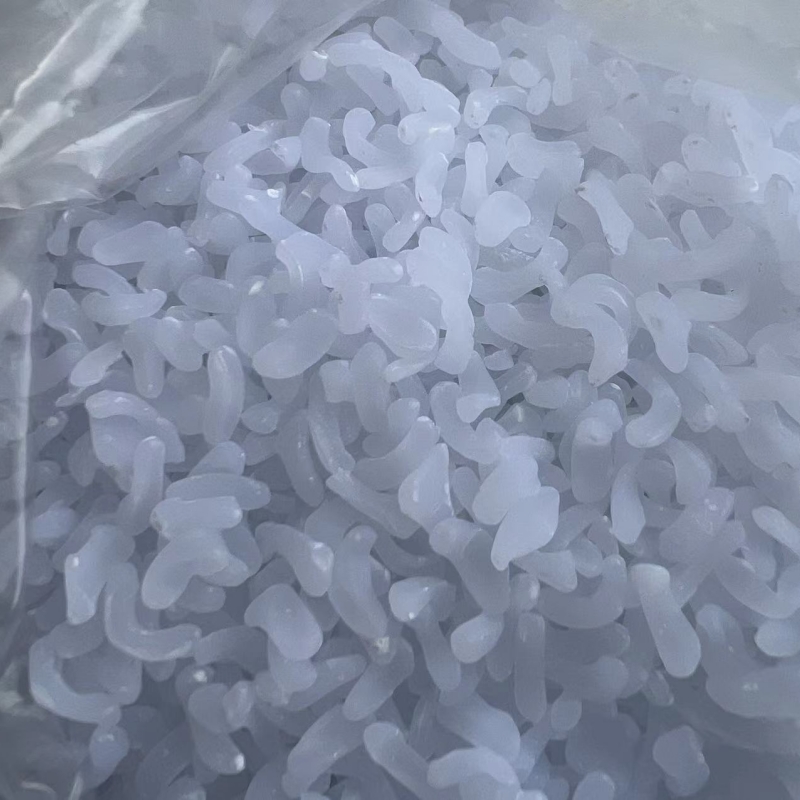

| Appearance | White pellets |

| Particle Size (particles/10g) | 200±50 |

| Volatile Matter at 105℃ (%) | ≤0.3 |

| Melt Flow Index (190℃, 5KG) g/10min | 4~10 |

| Melting Point (℃) | 125 |

| Density (g/cm²) | 2.5 |

| Filler Content (%) | ≤80 |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform