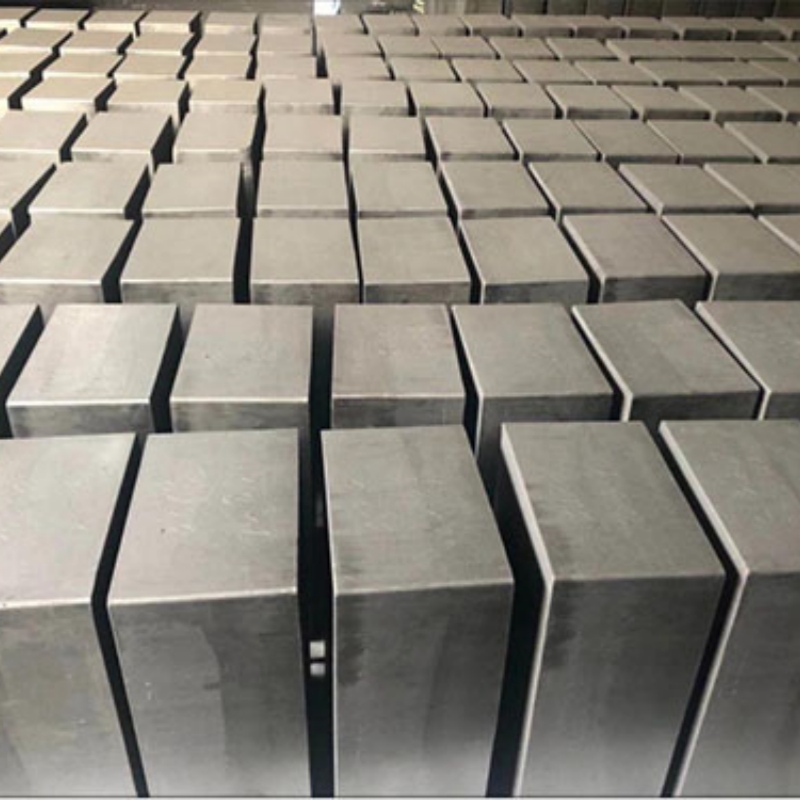

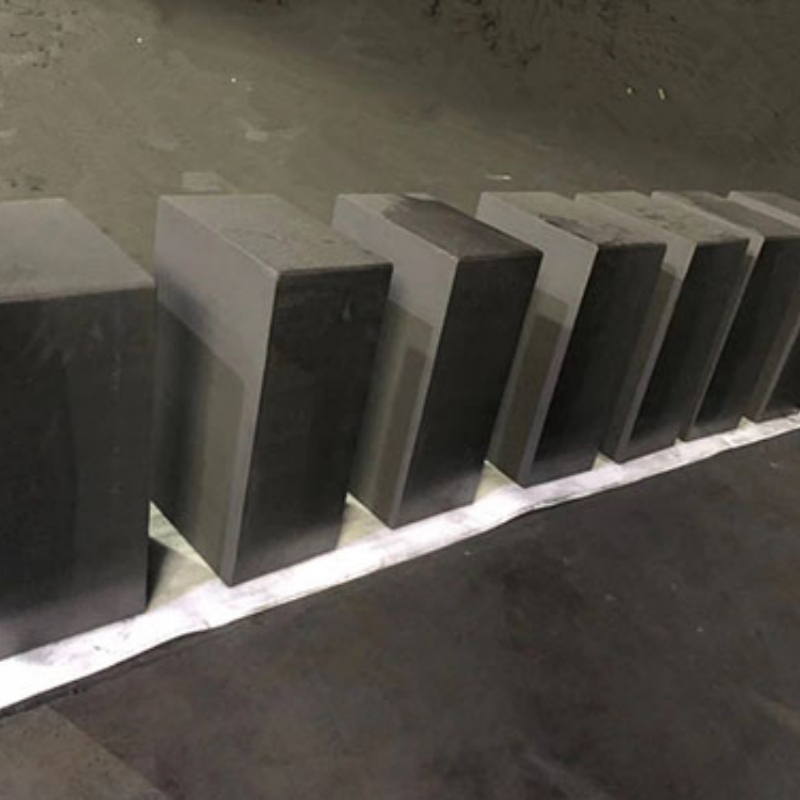

Molded graphite is a high-purity carbon material manufactured through advanced molding and machining processes to achieve precise density, uniform microstructure, and exceptional thermal and electrical properties. Engineered for durability and versatility, molded graphite exhibits excellent oxidation resistance, high mechanical strength, and optimized conductivity. It is widely used in aerospace components, semiconductor fabrication, high-temperature furnaces, industrial electrodes, and precision machining applications, ensuring long-term reliability in demanding environments.

Product Overview

Molded graphite is an inorganic non-metallic material known for its exceptional physical and chemical properties. It offers excellent electrical conductivity, high-temperature resistance, oxidation resistance, low resistivity, corrosion resistance, self-lubricating properties, thermal shock resistance, and ease of precision machining. Molded graphite is widely used across many high-tech industries, particularly in aerospace, solar photovoltaics, semiconductors, continuous casting, hard alloys, electronic mold sintering, and electrical discharge machining (EDM), where its unique advantages come to the fore. As a high-performance material, it has vast potential in high-tech and new technologies.

Features

- Excellent Electrical Conductivity: Suitable for high-current and high-temperature environments, ensuring efficient conduction.

- High-Temperature Resistance & Oxidation Resistance: Can operate at extremely high temperatures and has outstanding resistance to oxidation.

- Low Resistivity: With low electrical resistance, it improves the efficiency and durability of electric heating elements.

- Strong Corrosion Resistance: Ideal for use in harsh chemical environments, resistant to a wide range of corrosive substances.

- Self-Lubricating Properties: Reduces friction and extends the service life of components.

- Thermal Shock Resistance: Able to withstand rapid temperature changes without cracking.

- Ease of Precision Machining: Ideal for precision machining, meeting high-accuracy requirements.

Applications

- Diamond Tool Pressure Sintering: Used in the high-temperature sintering process of diamond tools, enhancing their strength and wear resistance.

- Mold Manufacturing: Widely used in the manufacturing of molds, especially for metal casting and plastic molding.

- Continuous Casting Molds for Aluminum, Copper, and Brass: Suitable for continuous casting processes for metals like aluminum, copper, and brass, providing stable mold materials.

- Degassing Rods: Used in the metallurgical industry as degassing rods, improving the quality of castings.

- Crucibles and Sealing Rods: Used in high-temperature smelting and chemical reactions, offering high resistance to heat and corrosion.

- Semiconductor Applications: Serves as a high-temperature, high-precision material in semiconductor manufacturing.

- Solar Technology Applications: Applied in the manufacturing of solar components and in high-temperature environments.

- EDM Applications: Used as electrode material in electrical discharge machining (EDM), providing high-precision machining capabilities.

| Grade | Density (g/cm³) | Resistivity (μΩ·m) | Thermal Conductivity (W/m·K) | Thermal Expansion (Room Temp-600℃) | Shore Hardness (HSD) | Bending Strength (MPa) | Compressive Strength (MPa) | Young’s Modulus (GPa) | Ash Content (PPM) | Industry Application |

| KYM-5 | 1.8 | 8~10 | 125 | 4.9 | 45 | 40 | 80 | 9.5 | 500 | Sintering & Continuous Casting Industry |

| KYX-5P | 1.9 | 8~10 | 135 | 3.6 | 55 | 55 | 105 | 12 | 500 | Sintering & Continuous Casting Industry |

| KYD-4 | 1.72 | 10~13 | 100 | 5 | 40 | 30 | 65 | 9.2 | 500 | Photovoltaic Industry |

| KYD-6 | 1.81 | 11~14 | 120 | 4.5 | 60 | 45 | 90 | 10.5 | 500 | Photovoltaic Industry |

| Grade | Density (g/cm³) | Resistivity (μΩ·m) | Shore Hardness (HSD) | Rockwell Hardness (HRL) | Bending Strength (MPa) | Average Particle Size (μm) | Industry Application |

| KYX-7 | 1.76 | 12~16 | 40 | 94 | 40 | 8 | EDM Industry |

| KYX-60 | 1.78 | 12~16 | 45 | 100 | 45 | 4 | EDM Industry |

| KYD-8 | 1.84 | 12~16 | 70 | 105 | 55 | 6 | EDM Industry |

| Grade | Density (g/cm³) | Resistivity (μΩ·m) | Thermal Conductivity (W/m·K) | Thermal Expansion (10⁻⁶/℃) | Shore Hardness (HSD) | Bending Strength (MPa) | Compressive Strength (MPa) | Young’s Modulus (GPa) | Average Particle Size (μm) | Industry Application |

| KYD-9 | 1.88~1.92 | 10~14 | 110 | 3.9 | 75 | 60 | 125 | 12 | 2 | 3D Curved Glass |

| KYD-30 | 1.81 | 15~19 | 80 | 5.8 | 80 | 43 | 130 | 7.5 | 12 | 3D Curved Glass |

| KYX-70 | 1.85 | 12~16 | 105 | 4 | 55 | 50 | 105 | 10 | 8 | 3D Curved Glass |

| KYX-60S | 1.85 | 12~16 | 110 | 4 | 60 | 55 | 120 | 11 | 4 | 3D Curved Glass |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform