Cyclohexanol dehydrogenation to cyclohexanone catalyst is a high-performance catalytic material designed for the selective dehydrogenation of cyclohexanol into cyclohexanone, ensuring efficient conversion and superior stability. Engineered with optimized metal-supported formulations, it enhances reaction kinetics, improves selectivity, and ensures prolonged operational lifespan for industrial applications. This catalyst is widely used in fine chemical synthesis, pharmaceutical intermediate production, and nylon precursor manufacturing, delivering reliable performance for continuous catalytic dehydrogenation.

Product Overview

The cyclohexanol dehydrogenation to cyclohexanone catalyst is a modified Cu-Zn-based catalyst with added special promoters, specifically designed for the cyclohexanol dehydrogenation process in caprolactam plants. The catalyst demonstrates a wide temperature tolerance range, maintaining good activity at lower temperatures and offering high selectivity and stability. Its characteristics allow it to operate stably at high space velocities, meeting the demands of large-scale industrial production. It also provides good economic and operational safety.

Key Features

- Wide Temperature Range: The catalyst maintains good catalytic activity over a wide range of temperatures.

- Good Low-Temperature Activity: Especially effective for cyclohexanol dehydrogenation reactions at low temperatures, improving conversion rates.

- High Selectivity: The catalyst has high selectivity, effectively converting cyclohexanol to cyclohexanone, reducing side reactions.

- Stable Performance: The catalyst maintains stable catalytic activity under high space velocity operating conditions, ensuring reliable long-term operation.

- Suitable for High Space Velocity Operations: It remains highly effective even under high space velocity conditions, enhancing reaction efficiency.

Applications

- Caprolactam Production: Widely used in caprolactam plants for the cyclohexanol dehydrogenation process to produce cyclohexanone.

- Petrochemical Industry: Used for the cyclohexanol dehydrogenation reaction to produce cyclohexanone, which is further used in the manufacture of caprolactam, nylon, and other chemicals.

- Catalytic Dehydrogenation Processes: Suitable for various catalytic dehydrogenation reactions, particularly in high space velocity, large-scale industrial production.

| Item | Data |

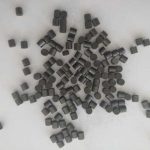

| Appearance | Black Flake-like |

| Specification (mm) | Ф 6 × (3.0 - 4.0) |

| Chemical Composition | CuO-ZnO-Additives |

| Bulk Density (kg/L) | 1.2 - 1.4 |

| Specific Surface Area (m²/g) | ≥50 |

| Radial Compressive Strength (N/cm) | ≥150 |

| Cyclohexanol Conversion Rate (%) | ≥50.0 |

| Cyclohexanone Selectivity (%) | ≥99.0 |

| Item | Data |

| Operating Temperature | 220 ℃-280 ℃ |

| Operating Pressure | Atmospheric or Slight Positive Pressure |

| Cyclohexanol Liquid Space Velocity | 0.4 h⁻¹ - 1.2 h⁻¹ |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform