Cr4+:YAG (Chromium-doped Yttrium Aluminum Garnet) crystal is a high-performance passive Q-switch material known for its excellent saturable absorption, high damage threshold, and broad absorption spectrum. Engineered with precise chromium doping, it enables efficient modulation of laser pulses without requiring active external components. Cr4+:YAG is widely used in solid-state lasers for medical, industrial, and scientific applications, ensuring stable and high-energy pulse generation with minimal thermal distortion.

Product Overview:

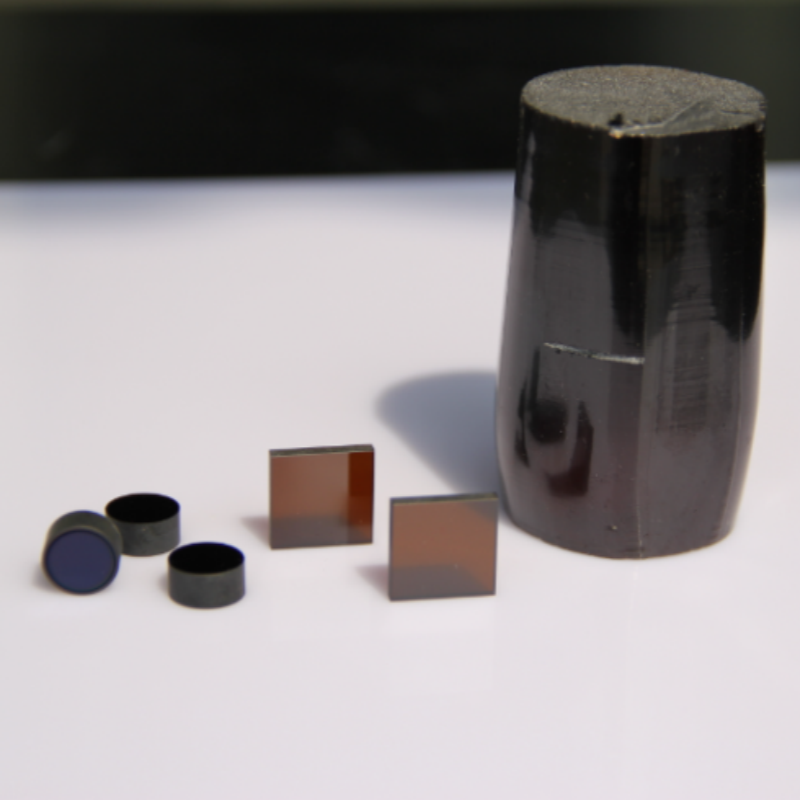

Cr4+:YAG crystal is an excellent saturable absorber material widely used in lasers operating in the 0.8-1.2μm wavelength range. Known for its strong absorption characteristics, this crystal also offers a high melting point, good thermal conductivity, damage resistance, and high stability. Cr4+:YAG is commonly used as a passive Q-switch in lasers within the 0.8-1.2μm wavelength range. Its long service life and high damage threshold make it ideal for high-power laser systems, serving as a critical component in various laser applications.

Key Features:

- Long Service Life:Suitable for use in environments requiring long-term, high-frequency operation.

- High Damage Threshold:Can withstand high laser power, making it ideal for demanding and high-power laser systems.

- High Stability:Provides stable and reliable performance, ensuring continuous operation of laser systems.

- High Reliability:Excellent operational stability, making it suitable for precision and high-performance applications.

Applications:

- Laser Systems:Used as a passive Q-switch material in lasers operating in the 0.8-1.2μm wavelength range.

- Laser Technology:Ideal for high-power laser systems that require high damage thresholds and long-term stability.

- Industrial and Scientific Research:Widely used in industrial laser processing, laser ranging, and laser sensing applications.

| Property | Value |

| Chemical Formula | Cr⁴⁺: Y₃Al₅O₁₂ |

| Crystal Orientation | [100] or [111] |

| Initial Absorption Coefficient | 0.5~6 cm⁻¹ @ 1064nm |

| Initial Transmittance | 5%~95% @ 1064nm |

| Component Dimensions | Diameter: 3~12mm, Cross-section: 2×2~30×30mm |

| Dimensional Tolerance | Diameter: +0, -0.02mm, Thickness: +0.2, -0mm |

| Cylindrical Surface Processing | Fine grinding |

| End Face Parallelism | ≤10″ |

| End Face Flatness | λ/10 per inch @ 632.8nm |

| Surface Finish | 10⁻⁵ (MIL-PRF-13830B) |

| Anti-Reflective Coating Reflectance | R < 0.15% @ 1064nm |

| Laser Damage Threshold of Coating | >750 MW/cm² |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform