BMC Moldable Plastic (Bulk Molding Compound) is a high-performance thermosetting composite designed for superior mechanical strength, chemical resistance, and moldability. It is widely used in aerospace, automotive, electrical, and industrial applications requiring precision, durability, and efficient processing.

Product Description:

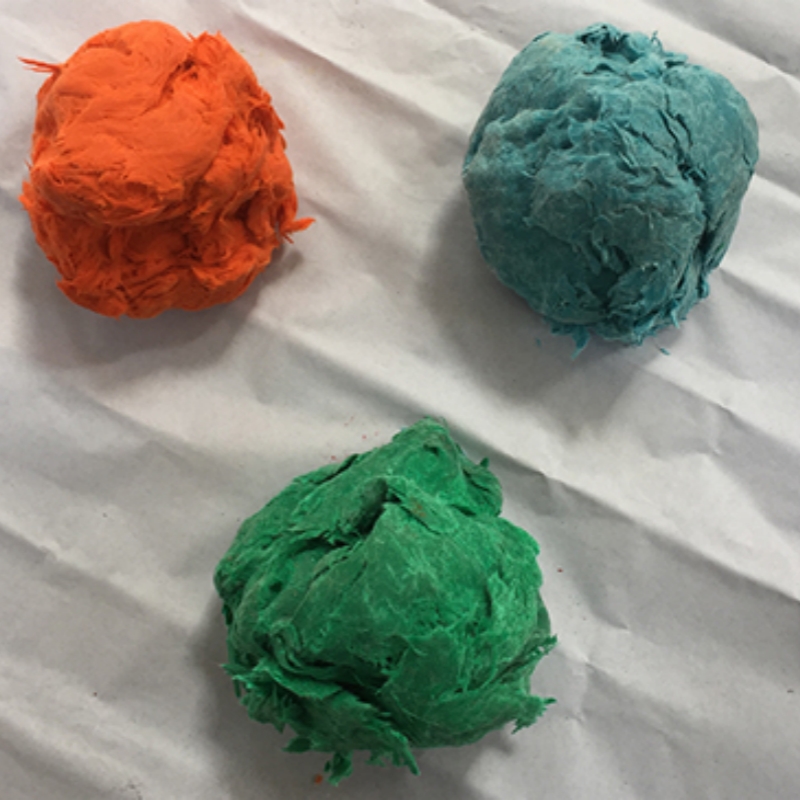

BMC (Bulk Molding Compound) is a composite material known for its exceptional electrical properties, flame retardancy, and stability. Available in a granular form, it is easy to process and widely used in the automotive, home appliance, and electrical component industries for encapsulation and molding. The material features zero shrinkage, ensuring high precision in processing and reliable performance in harsh environments.

Product Features:

- Excellent Electrical Properties:BMC has excellent insulation properties, making it ideal for use in electrical and electronic devices.

- Flame Retardancy:Designed with strong flame-retardant characteristics, BMC helps reduce fire risks effectively.

- High Stability:The material has good thermal stability and aging resistance, ensuring long-term reliable performance.

- Zero Shrinkage:The zero-shrinkage property ensures no deformation during processing and usage, guaranteeing high precision and stability in the final product.

Applications:

- Automotive Lighting:Widely used in the automotive industry, particularly for headlamp housings, offering excellent heat resistance and electrical properties.

- Electrical Encapsulation:Used in home appliances, electrical devices, and other applications for encapsulation and casing, providing durable protection.

- Electrical Components:Commonly used for the production of electrical components, such as high-voltage electrical equipment and electronic part encapsulation, ensuring excellent electrical insulation and aging resistance.

| No. | Test Item | Unit | BMC-1 | BMC-2 | BMC-3 | Test Method | |

| 1 | Appearance | - | Smooth, flat, no bubbles, no cracks | - | |||

| 2 | Density | g/cm³ | 1.75~1.95 | 1.75~1.95 | 1.75~1.95 | GB 1033 | |

| 3 | Water Absorption | % | ≤0.2 | ≤0.2 | / | GB 1034 | |

| 4 | Molding Shrinkage Rate | % | ≤0.15 | ≤0.15 | ≥0.30 | ISO 2577 | |

| 5 | Flexural Strength | Mpa | ≥90 | ≥80 | ≥70 | GB 9341 | |

| 6 | Impact Strength (Notched) | KJ/m² | ≥30 | ≥25 | ≥20 | GB 1043 | |

| 7 | Heat Deflection Temperature | °C | ≥240 | ≥240 | ≥220 | GB 1634 | |

| 8 | Insulation Resistance | Normal State | Ω | ≥1.0x10¹³ | ≥1.0x10¹³ | ≥1.0x10¹² | GB 1410 |

| After Immersion for 24 Hours | ≥1.0x10¹² | ≥1.0x10¹² | / | ||||

| 9 | Dielectric Strength (in Transformer Oil at 90°C) | Mv/m | ≥12.0 | ≥12.0 | ≥10.0 | GB 1408 | |

| 10 | Dielectric Loss Factor (IMHZ) | - | ≤0.015 | ≤0.015 | / | GB 1409 | |

| 11 | Relative Dielectric Constant (IMHZ) | - | ≥4.5 | ≥4.8 | / | GB 1409 | |

| 12 | Arc Resistance | S | ≥180 | ≥180 | ≥150 | GB 1411 | |

| 13 | Tracking Resistance Index (PTI) | V | ≥600 | ≥600 | ≥600 | GB 4027 | |

| 14 | Flammability | Class | FVO | FVO | FVO | GB 5169.16 | |

| 15 | Long-term Heat Resistance Temperature Index | °C | 155 | 155 | 130 | GB 11026 | |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform