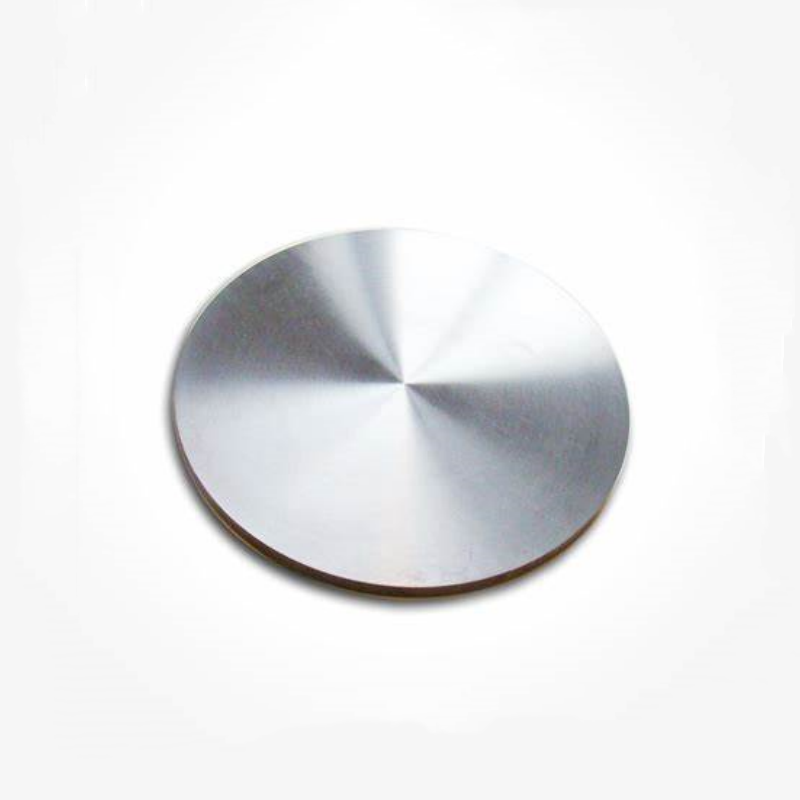

Aluminum-strontium alloy (ALSr10) is a high-performance metallurgical material designed for grain refinement and structural enhancement in aluminum-based alloys. It is widely used in automotive manufacturing, aerospace engineering, and precision casting applications. Due to its ability to improve mechanical properties and thermal stability, aluminum-strontium alloy plays a crucial role in advanced material development, sustainable engineering, and high-performance industrial solutions.

Product Overview

Aluminum strontium alloy (ALSr10) contains 9–11% strontium and is specifically designed as a long-lasting modifier for aluminum-silicon alloys. The addition of strontium significantly improves the grain structure of aluminum-silicon alloys, refining the silicon grains, and enhancing the alloy's strength, toughness, and heat resistance. This alloy is widely used for modifying aluminum-silicon alloys, improving the overall performance of aluminum alloys, especially in applications requiring long-term stable performance.

Key Features

- The strontium content (9–11%) effectively refines the grain structure of aluminum-silicon alloys, improving their strength and toughness.

- Suitable for aluminum-silicon alloys with less than 13% silicon content, used as a long-lasting modifier.

- Enhances the heat resistance, oxidation resistance, and machinability of the alloy.

- Good plasticity and machinability, allowing for customization into different shapes as needed.

- Maintains stability and performance of the alloy during long-term high-temperature use.

Applications

- Aluminum Alloy Production:Used for modifying aluminum-silicon alloys, particularly as a long-lasting modifier during the production of aluminum-silicon alloys.

- Automotive Industry:Applied in aluminum alloy engine and transmission components to improve their strength, toughness, and heat resistance.

- Aerospace:Used to enhance the performance of aluminum alloy structural parts in aircraft, especially in high-temperature environments.

- Metallurgical Industry:Used during the aluminum alloy smelting process to improve the fluidity and casting properties of aluminum-silicon alloys.

- Machinery Manufacturing:Used in the production of aluminum alloy components that require high strength and heat resistance, improving their overall performance.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform