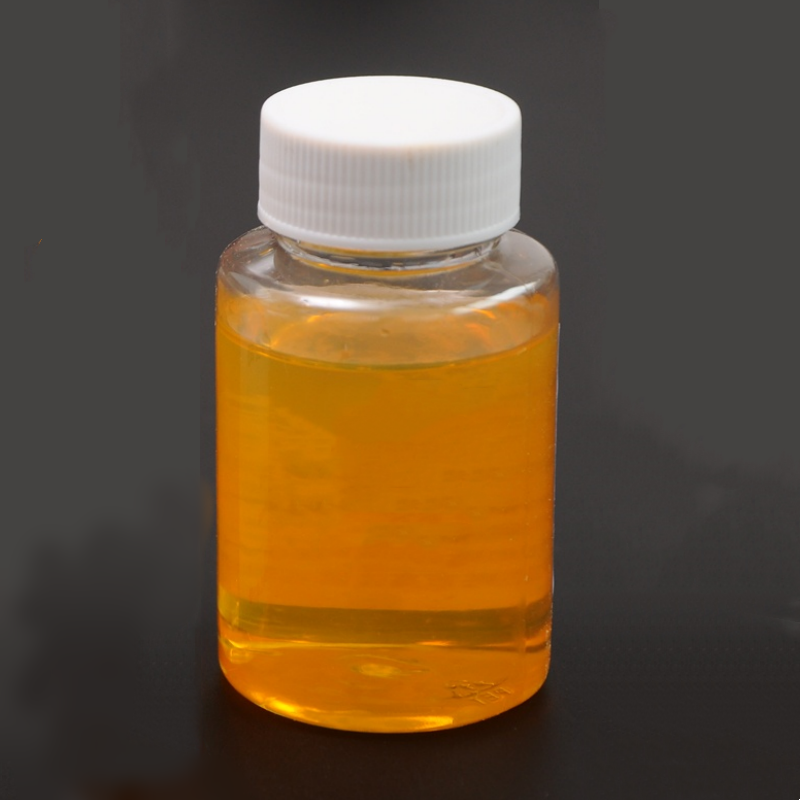

Demulsifier efficiently breaks emulsions, separates oil and water phases, and optimizes industrial fluid treatment. Designed for petrochemical processing, wastewater purification, and crude oil separation, it ensures effective emulsion destabilization, enhanced separation efficiency, and improved operational performance.

Product Overview:

A demulsifier is a surfactant designed to break the structure of emulsified liquids, causing the separation of different phases in an emulsion. It efficiently separates the organic phase and the water phase by eliminating the emulsion interface, enabling phase separation. The effectiveness of the demulsifier is crucial for achieving successful separation, and different types of demulsifiers vary in their ability to break emulsions, so the selection of the appropriate demulsifier must be tailored to the characteristics of the emulsion.

Product Features:

- Effective Separation:Efficiently breaks the emulsion structure and promotes phase separation.

- Various Types:Includes anionic, cationic, nonionic, and amphoteric demulsifiers, suitable for different applications.

- Targeted Action:The demulsifier is selected based on the characteristics of the emulsion to ensure optimal separation performance.

- Wide Range of Applications:Can be applied to a variety of emulsion systems.

Applications:

- Petroleum Industry:Commonly used for demulsification during oil extraction, separating the water phase and oil phase from crude oil.

- Chemical Industry:Used to separate emulsified liquids, improving the efficiency of production processes.

- Wastewater Treatment:Widely applied in treating oily wastewater to enhance the separation of water and oil and improve water quality.

- Food and Daily Chemical Products:Used for demulsification in emulsified liquids, helping separate different liquid components.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform