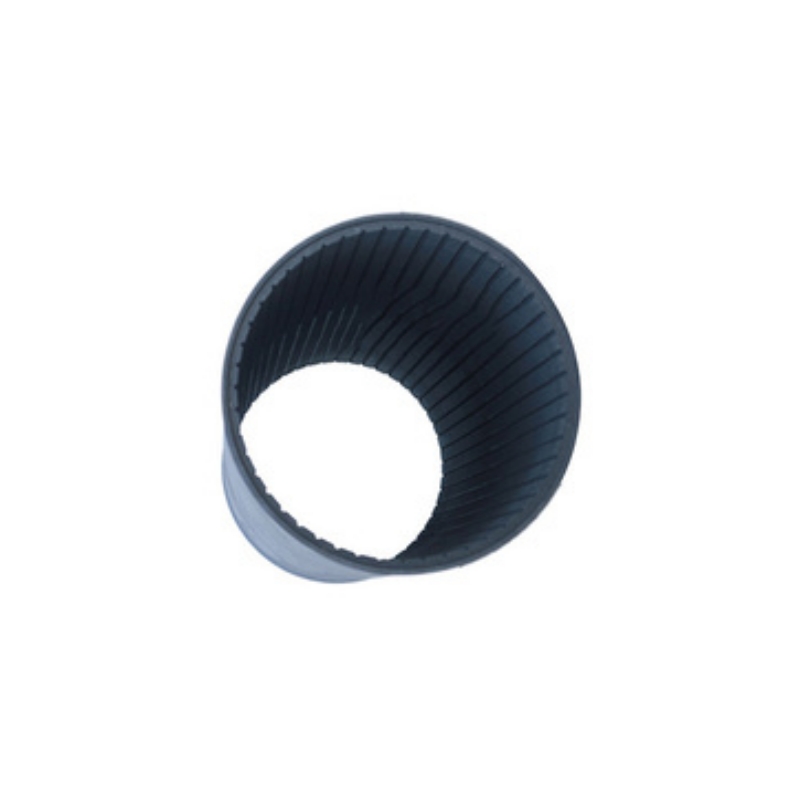

Vacuum furnace graphite parts are precision-engineered carbon components designed for high-temperature industrial applications requiring superior thermal stability, minimal outgassing, and excellent mechanical strength. Manufactured using high-purity graphite, these parts provide optimized heat resistance, extended lifespan, and enhanced structural integrity, ensuring reliable performance in extreme vacuum conditions. They are widely used in semiconductor processing, aerospace engineering, metallurgical refining, and high-temperature furnace systems, guaranteeing efficient thermal management and contamination-free operation.

Product Overview

Vacuum furnace graphite parts are manufactured from high-purity graphite materials and are specifically designed for use in vacuum furnace equipment. These components possess exceptional high-temperature resistance and excellent chemical stability. Through precision machining and customized design, they meet the demanding requirements of high-temperature and high-vacuum environments. They are widely used in vacuum heat treatment, metal smelting, and other high-temperature industrial processes.

Key Features

- High-Temperature Resistance: Maintains stability under extreme temperatures, making it ideal for use in vacuum furnaces and other high-temperature equipment.

- High Chemical Stability: Offers excellent oxidation and corrosion resistance, withstanding exposure to various chemical agents.

- Good Thermal Conductivity: High thermal conductivity ensures uniform and rapid heat distribution, improving temperature stability within the furnace.

- Dimensional Stability: Excellent dimensional stability and strength, with minimal deformation under high-temperature conditions, ensuring long service life.

- Superior Mechanical Properties: High compressive strength and wear resistance, suitable for harsh working environments.

Applications

- Vacuum Heat Treatment: Used extensively in vacuum furnaces for critical components such as heating elements, electrodes, and furnace linings.

- Metal Smelting and Casting: Applied in the high-temperature environment of metal smelting as heat-resistant components.

- Semiconductor Manufacturing: In the semiconductor industry, used in vacuum furnaces and equipment for their high-temperature and oxidation resistance.

- High-Temperature Experiments: Suitable for use in experimental equipment requiring high vacuum and high-temperature processing.

- Aerospace: Used in aerospace applications for sealing, heating, and supporting materials in high-temperature environments.

new material

new material