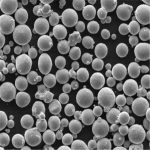

TC4 Titanium Alloy Powder is a high-performance material widely used in aerospace, automotive, and medical industries. It is renowned for its excellent corrosion resistance, high strength-to-weight ratio, and exceptional biocompatibility, making it ideal for additive manufacturing and other advanced engineering applications.

Product Overview

TC4 Titanium Alloy Powder is composed primarily of titanium, aluminum, and vanadium, offering excellent strength, corrosion resistance, and good weldability. This alloy powder is widely used in aerospace, medical, automotive, and other high-demand fields, especially for 3D printing and powder metallurgy technologies.

Product Features

- Excellent Strength and Toughness:Provides high strength while maintaining good toughness, making it suitable for parts subject to complex stresses.

- Good Corrosion Resistance:Performs well in humid, marine, and chemical environments, offering excellent corrosion resistance.

- Good Processability:Suitable for precision processing using powder metallurgy and additive manufacturing technologies.

- Lightweight Characteristics:Offers low density, ideal for high-performance applications that require weight reduction.

Applications

- Aerospace:Used for aircraft components, engine parts, and other applications requiring high strength and lightweight materials.

- Medical Industry:Used to manufacture medical devices such as implants and prosthetics, offering good biocompatibility.

- Automotive Industry:Applied in lightweight automotive components to improve fuel efficiency and reduce vehicle weight.

- Advanced Manufacturing Technologies:Ideal for 3D printing, powder metallurgy, and other manufacturing processes, producing complex structural components.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform