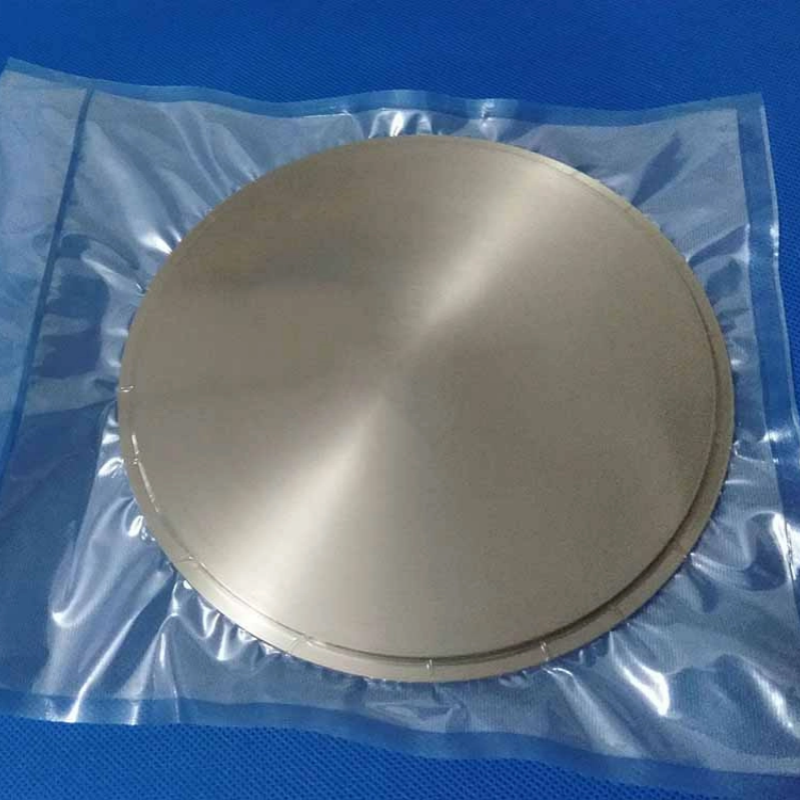

Solid Sodium Silicate is a hard, glass-like inorganic compound produced through high-temperature processing of silica sand and sodium carbonate. It is widely used in industrial applications, including detergents, adhesives, ceramics, and paper production. Known for its high durability, corrosion resistance, and binding properties, it plays a crucial role in various manufacturing processes.

Product Overview

Solid sodium silicate is a compound formed by the combination of silicon, oxygen, sodium, and other elements, typically found in the form of solid granules or powder. It is widely used in adhesives, fillers, and as a chemical raw material, particularly in the foundry industry, where it plays a crucial role as a binder. Due to its excellent chemical stability and versatility, solid sodium silicate has broad applications across several industrial fields.

Product Features

- High Stability: Offers high chemical stability, making it suitable for various industrial environments.

- Excellent Adhesion: Exhibits superior adhesion properties in casting, filling, and other industrial applications.

- Easy to Store: The solid form is easy to store and transport, with a long shelf life.

- Versatility: Can be used as an adhesive, filler, and in other chemical processes.

Applications

- Adhesive: Used as a binder in the foundry industry and other applications requiring adhesion.

- Filler: Acts as a filler in the chemical industry, improving the physical properties of products.

- Chemical Raw Material: An essential raw material in chemical production, involved in various chemical reactions and product synthesis.

- Foundry Industry: Used as a binder in mold making, helping improve casting quality and production efficiency.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform