Semiconductor-Specific Molybdenum Disilicide (MoSi₂) Heating Elements deliver ultra-stable high-temperature performance (1800°C+), oxidation resistance, and contamination-free heating for critical semiconductor manufacturing processes.

Product Overview

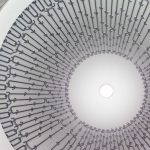

The semiconductor-specific MoSi₂ heating element is a high-performance heating component designed specifically for semiconductor furnaces, wafer heating, and other high-temperature applications. This product is manufactured using precision processing techniques and provides high heating power and stable heat distribution, ensuring excellent heating performance across various applications. MoSi₂ material offers high-temperature strength, corrosion resistance, and extended service life, making it especially suitable for heating systems that require high precision and operation under extreme temperature conditions.

Features

- High Heating Power: Precisely manufactured to deliver an efficient and uniform heat distribution, ensuring stable operation of the equipment.

- Customizable Shape: Can be customized in different shapes based on customer needs, ensuring stable performance and extended service life in diverse applications.

- High Surface Load Capacity: Compared to metallic wire heating elements, MoSi₂ elements can withstand higher surface loads and operate efficiently in rapid heating and cooling environments.

- Adaptability to Different Sizes: Suitable for both small and large semiconductor wafers, capable of adapting to various sizes and application scenarios.

- High-Temperature Cleanliness: Ensures the cleanliness of equipment during high-temperature operations, making it ideal for semiconductor production processes.

- Dense Protective Coating: Features a complete protective layer that prevents shedding, enhancing the element's durability.

- Excellent Mechanical Properties: Robust soldering joints, high impact resistance, and precise bending geometry, meeting custom requirements.

- High Density and High Conductivity: High-density material with excellent electrical conductivity, enabling rapid heating and higher energy efficiency, helping reduce production costs.

- High Temperature Strength and Resistance: Exceptional high-temperature strength, capable of handling substantial loads at elevated temperatures and ensuring long-term stable operation.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform