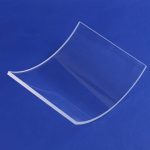

Quartz wafer is a high-purity, precision-engineered component designed for advanced semiconductor processing, optical applications, and scientific research. Manufactured using refined quartz materials, it ensures superior thermal stability, minimal thermal expansion, and excellent chemical resistance. Its exceptional flatness and optical clarity make it ideal for integrated circuits, photonics, and precision metrology applications.

Product Overview

Quartz wafers are made from high-purity quartz and are extensively used in the photovoltaic (PV) industry for annealing, heating, and thermal treatment processes. Their excellent high-temperature resistance allows them to operate stably in extreme temperature environments, and their low thermal expansion coefficient helps prevent damage caused by thermal stress. These wafers significantly enhance thermal efficiency in solar cell production, ensuring high process stability and efficiency.

Key Features

- High-Purity Quartz: Ensures no impurity release in high-temperature environments, maintaining the quality of photovoltaic products.

- High-Temperature Resistance: Extremely high resistance to heat, capable of withstanding temperatures above 1000°C, making it ideal for high-temperature processes.

- Low Thermal Expansion Coefficient: Reduces the impact of temperature changes, prolonging the product's service life and ensuring stable performance.

- Excellent Chemical Stability: Highly resistant to chemical corrosion, suitable for high-temperature, low-oxygen environments in production processes.

- Good Mechanical Properties: Quartz wafers maintain their shape even at high temperatures, ensuring smooth operations during production.

Applications

- Photovoltaic Industry: Widely used in solar cell production, especially in annealing furnaces and heating processes, acting as a supporting and thermal treatment material.

- Solar Cell Manufacturing: Applied during the heat treatment of photovoltaic cells, providing excellent heat transfer and support.

- High-Temperature Heat Treatment: Suitable for high-temperature, low-oxygen heating and thermal treatment processes in various industries.

- Semiconductor Manufacturing: Used in semiconductor production for high-temperature furnace processes, providing stable support for materials.

new material

new material