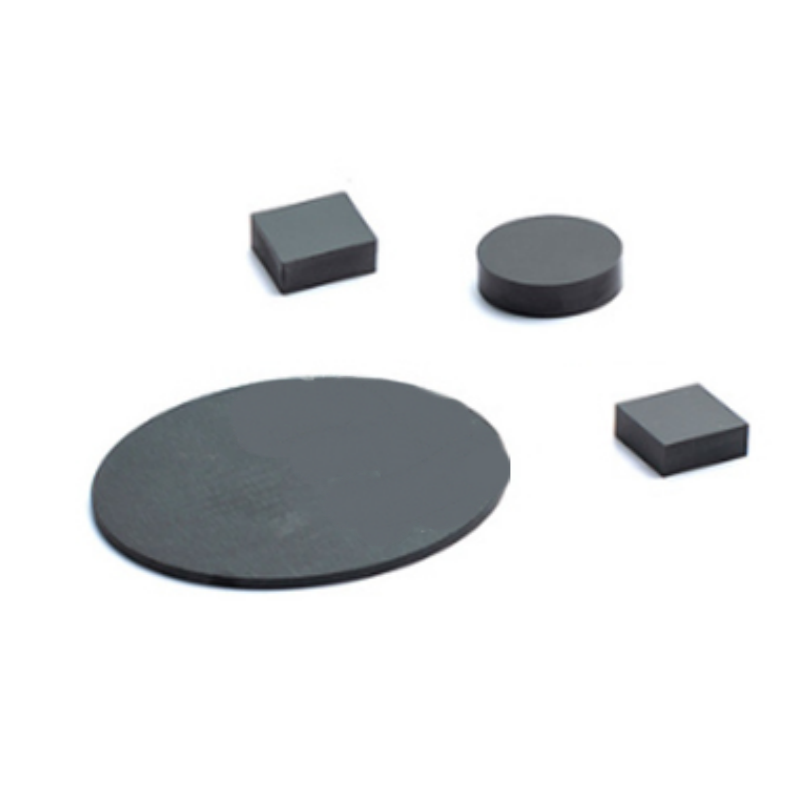

PCBN diamond blanks are high-performance polycrystalline cubic boron nitride (PCBN) materials engineered for precision cutting, grinding, and machining applications requiring extreme hardness, thermal stability, and wear resistance. Designed for heavy-duty industrial tooling, these blanks exhibit superior durability and oxidation resistance, making them ideal for high-speed machining in aerospace, automotive, metalworking, and semiconductor industries. With an optimized microstructure, PCBN diamond blanks ensure extended tool lifespan and reliable performance under demanding operational conditions.

Product Overview

Polycrystalline cubic boron nitride (PCBN) composite blanks are made from high-quality cubic boron nitride (CBN) micron powder combined with a special ceramic bonding system. Through careful design and processing, these blanks offer outstanding wear resistance, thermal stability, and chemical stability. They are widely used in high-performance cutting tools, especially for machining hard and complex materials, offering superior machining accuracy and tool life.

Features

- Exceptional Wear Resistance: High-purity cubic boron nitride gives PCBN excellent wear resistance, making it ideal for demanding cutting environments.

- Thermal and Chemical Stability: PCBN maintains excellent thermal stability under high temperatures, suitable for high-temperature machining, and offers strong chemical stability.

- High Impact Resistance: PCBN materials have strong impact resistance, ensuring stable performance even under high-load conditions.

- High CBN Content: With a high content of cubic boron nitride, PCBN is particularly effective for machining hard materials like cast iron.

- Uniform Microstructure: The precise microstructure design ensures consistent performance during cutting, extending tool life.

Applications

- Cast Iron Machining: PCBN is particularly effective for machining cast iron, ductile iron, and other hard materials, especially in high-speed machining of gray cast iron.

- Tool Manufacturing: Widely used in manufacturing various cutting tools, including components with high wear resistance requirements, such as engine parts and cylinder heads.

- Powder Metallurgy and Metal Machining: Suitable for precision machining of hard materials such as powder metallurgy, hardened steels, tool steels, mold steels, and bearing steels.

- Complex Material Machining: Can be used to machine high-hardness alloys, cobalt-nickel-based alloys, and other special materials, offering high toughness and extended tool life.

| Grade | Machining Type | Applicable Industries | Processed Materials | Characteristics |

| FBN3500 | Rough Machining | Rollers, Slurry Pumps, Roller Wall | High nickel-chromium, high-hardness alloy cast iron, cast high-speed steel, high manganese steel | Higher hardness, excellent impact resistance, and good edge stability; suitable for heavy-duty rough machining from intermittent to continuous conditions |

| FBN7630 | Rough Machining / Semi-Finish Machining | Brake Discs, Brake Drums, Compressor Parts | Gray Cast Iron | Better combination of toughness and wear resistance, good edge stability; versatile, suitable for high-speed rough and finish machining from intermittent to continuous conditions |

| FBN9500 | Rough Machining / Semi-Finish Machining | Gears, Bearings, Mining Machinery, Coal Mining Machinery | Hardened Steel, Surface Overlay Materials | Balanced impact toughness and good wear resistance; suitable for heavy intermittent to continuous machining conditions |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform