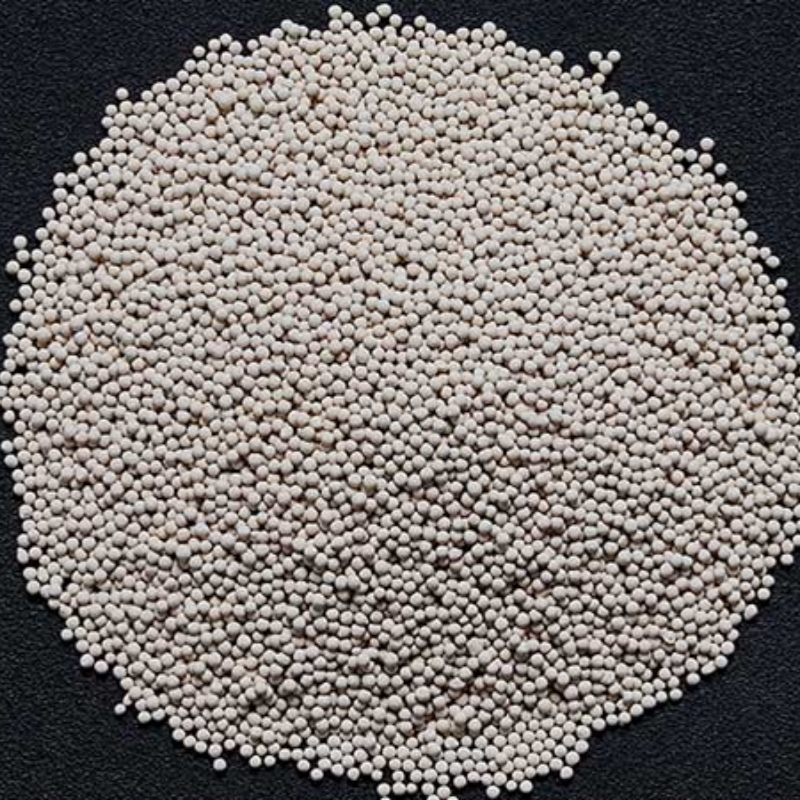

Oxygen production molecular sieve is a high-performance adsorbent designed for efficient gas separation and purification in oxygen generation processes. Featuring an optimized microporous structure with superior nitrogen adsorption capacity, it selectively removes nitrogen, enabling high-purity oxygen production through pressure swing adsorption (PSA) technology. This molecular sieve is widely used in medical oxygen concentrators, industrial oxygen generation, and air separation units, ensuring stable and efficient oxygen supply for various applications.

Product Overview

Oxygen Production Molecular Sieve is an artificially synthesized aluminosilicate crystal with an exceptional specific surface area and a uniform mesoporous structure. Its unique design provides high efficiency in drying and separation, preventing co-adsorption during the separation process and ensuring high yield. This molecular sieve can simultaneously perform drying and substance purification within the same system, making it ideal for adsorption processes at elevated temperatures. With excellent regeneration properties, it offers low operating costs and long-term reliability, making it a preferred choice in industrial oxygen production and other gas separation applications.

Specially manufactured for oxygen production, this molecular sieve is capable of efficiently separating oxygen from nitrogen, providing a high oxygen yield. Its superior adsorption and desorption performance, coupled with its ability to maintain good adsorption capacity at high temperatures, makes it suitable for Pressure Swing Adsorption (PSA) and Cryogenic Air Separation oxygen production. It is widely used in industries such as refining, chemicals, fertilizers, pharmaceuticals, steel, and alcohol production.

Key Features

- Efficient Oxygen-Nitrogen Separation: Provides exceptional oxygen-nitrogen separation, ensuring high oxygen purity to meet various industrial needs.

- Excellent Regeneration Performance: Efficiently desorbs adsorbed materials, ensuring long-term reuse and lowering operational costs.

- Broad Application: Suitable for large, medium, and small-scale PSA and cryogenic air separation oxygen production, as well as oxygen production in various industries.

- High Adsorption Capacity: Maintains good adsorption performance even at elevated temperatures.

- High Temperature Stability: Retains strong adsorption capability at high temperatures, ensuring stable and continuous operation.

Applications

- Pressure Swing Adsorption (PSA) Oxygen Production: Used for oxygen production and purification, widely applied in medical oxygen, industrial oxygen, and other fields.

- Cryogenic Air Separation Oxygen Production: Suitable for cryogenic air separation units, ensuring effective separation of oxygen from air.

- Gas Separation: Applied in refining, chemicals, fertilizers, pharmaceuticals, steel, and alcohol industries for gas separation and purification.

- Oxygen-Enriched Gas Production: Used in industries with high oxygen demand, such as metallurgy, chemicals, and more.

new material

new material