Non-hydrogenated pour-point depressant catalyst is a high-performance catalytic material designed to optimize the flow properties of petroleum-based fuels and lubricants at low temperatures. Engineered using advanced polymer-modifying catalysts, it effectively reduces the pour point without requiring hydrogenation, maintaining superior stability and performance. This catalyst is widely used in fuel refining, lubricant optimization, and industrial fluid processing, ensuring reliable functionality in extreme temperature conditions.

Product Overview:

The Non-Hydrogenated Pour-Point Depressant Catalyst is specifically designed for the catalytic dewaxing of heavy diesel, effectively lowering the pour point of oils and producing low-pour-point diesel, gasoline, liquefied gas, and other products. This catalyst uses the NKF-5 molecular sieve as its base material, offering high catalytic activity and excellent resistance to water vapor. It is widely applied in fields such as hydrotreated tail oil pour-point depressant, lubricant base oil production, and waste plastic catalytic cracking, earning significant market recognition.

Key Features:

- Low Pour Point Performance:Capable of lowering the pour point of oils to below -35°C, significantly improving low-temperature fluidity.

- High Gasoline Octane Rating:Gasoline produced has an octane rating ranging from 75 to 93, ensuring high product quality and yield.

- Low Energy Consumption and Long Lifespan:The catalyst consumes very little hydrogen during the reaction, with a single-use life exceeding 1000 hours. It also has a long usage cycle and a short regeneration period, typically lasting for over a year.

- Good Stability:The catalyst maintains stable reaction performance at low operational pressures, is easy to operate, and ensures reliable product quality.

- Customization Capability:The catalyst’s process can be adjusted based on customer needs to optimize the ratio of diesel, gasoline, and liquefied gas, meeting different user requirements.

Applications:

- Diesel Dewaxing and Pour-Point Depressant:Widely used in the dewaxing and pour-point depression of heavy diesel, producing low-pour-point diesel.

- Lubricant Base Oil Production:Applied in the hydrotreated tail oil pour-point depression process, producing high-quality lubricant base oils.

- Waste Plastic Catalytic Cracking:Used in the catalytic cracking of waste plastics to produce gasoline and diesel.

- Fine Chemicals Industry:Suitable for the production of high-octane gasoline and liquefied gas, with broad applications in fuel production.

| Item | Index | Analysis Method |

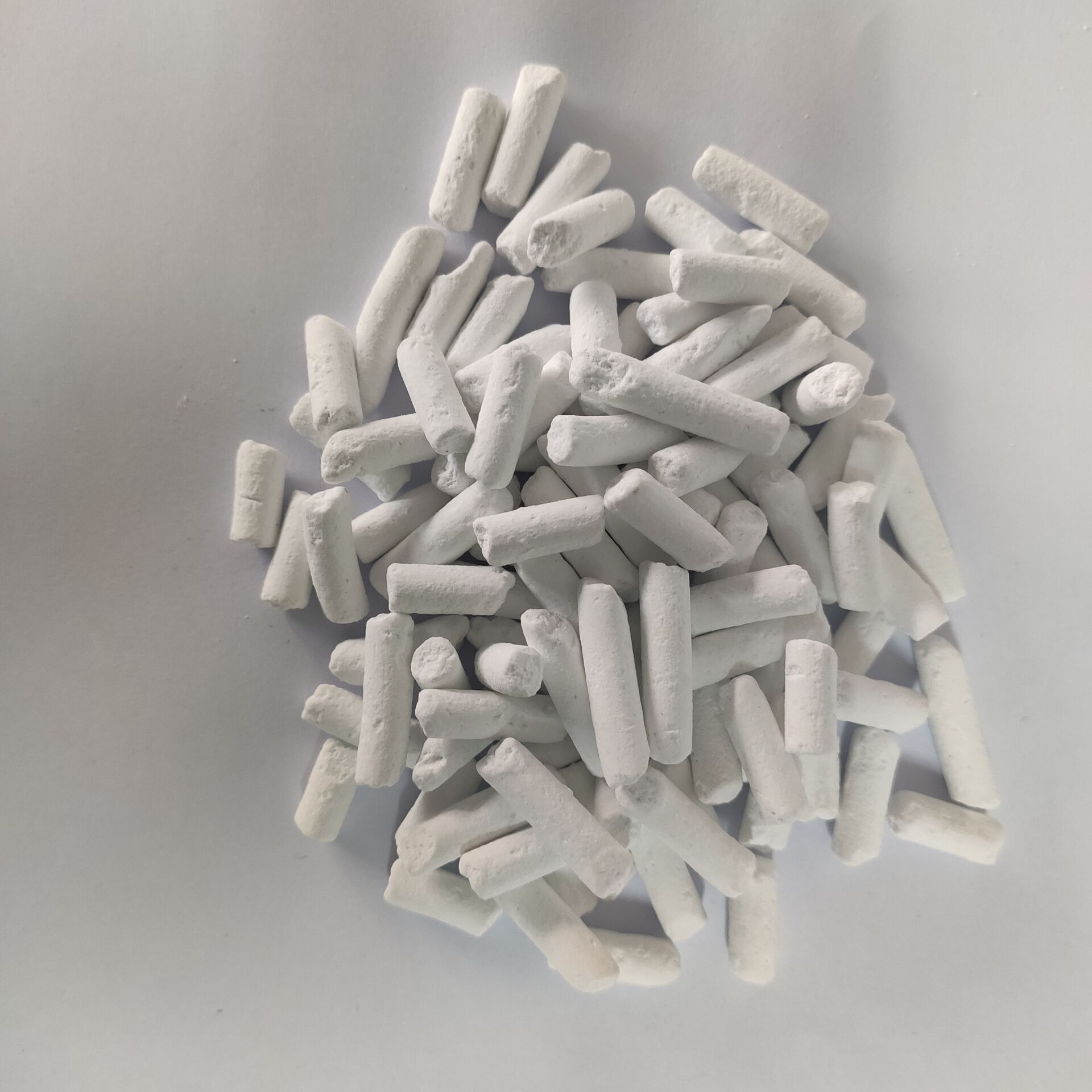

| Colour | White | Visual inspection |

| Shape | Cylinder | Visual inspection |

| Diameter (mm) | 1.8~2.2 | Caliper measurement (20 grains) |

| Length (mm) | ≤15 | Caliper measurement (20 grains) |

| Pore Volume (ml/g) | ≥0.17 | Low-temperature nitrogen adsorption |

| Surface Area (BET) m²/g | ≥320 | Low-temperature nitrogen adsorption |

| Compressive Strength (N/cm) | ≥110 | Intensity meter |

| Bulk Density (g/cm³) | 0.5~0.6 | Cylinder method |

new material

new material