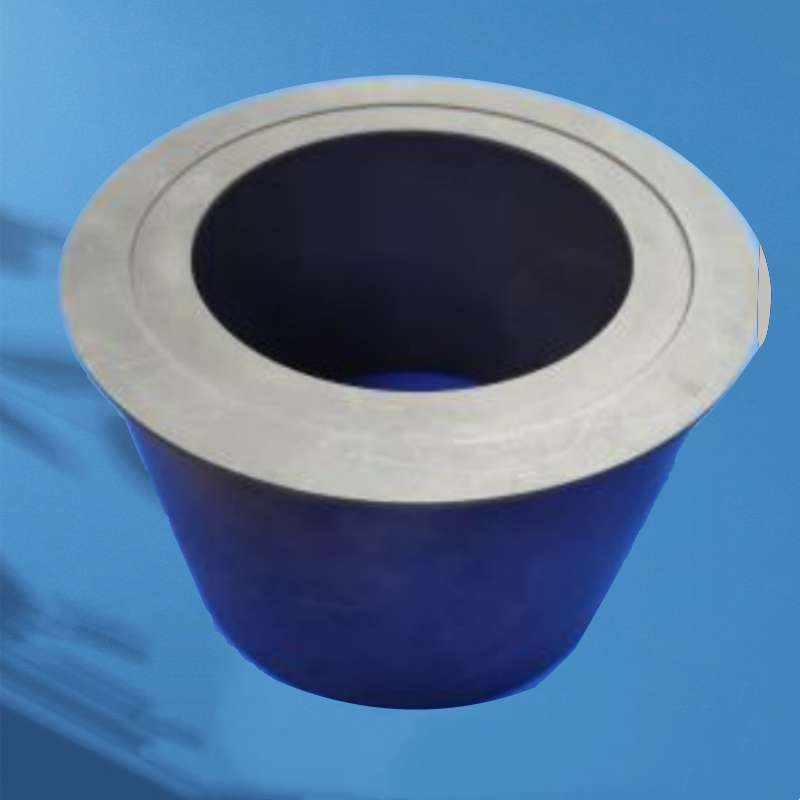

The MOCVD turntable support cylinder is a precision-engineered graphite component designed for metal-organic chemical vapor deposition (MOCVD) systems in semiconductor and optoelectronic manufacturing. This cylinder provides superior thermal stability, exceptional mechanical strength, and excellent chemical resistance, ensuring uniform rotation and structural integrity in high-temperature environments. Manufactured from high-purity graphite using advanced processing techniques, it supports reliable wafer handling, epitaxial growth, and thin-film deposition, optimizing operational efficiency in demanding industrial applications.

Product Overview

The MOCVD turntable support cylinder is a supporting component used in the Metal Organic Chemical Vapor Deposition (MOCVD) process. Its primary purpose is to provide stable support and positioning for the turntable inside the reactor. Manufactured with precision and uniform coating treatment, the support cylinder ensures stability and excellent mechanical performance under high-temperature conditions. It is widely used in high-precision manufacturing in industries such as semiconductors, LEDs, and optoelectronics.

Key Features

- High-Temperature Stability: Made from high-temperature resistant materials, ensuring stable operation and long-term durability in high-temperature environments.

- Precise Dimensions and Coating Thickness: Manufactured with high precision to ensure accurate dimensions and uniform coating thickness, enhancing overall performance.

- Corrosion Resistance: The material offers excellent resistance to corrosion, making it suitable for the chemical environment required by MOCVD processes.

- High Mechanical Strength: Provides sufficient support to ensure the stability of the turntable and the precision of the reaction process.

Applications

- Semiconductor Manufacturing: Used to support the turntable in MOCVD reactors, ensuring precise positioning and stability during the reaction process.

- LED Manufacturing: Widely used in LED production to improve deposition uniformity and production efficiency.

- Optoelectronics: Used in the manufacturing of optoelectronic components, offering essential mechanical support and high-temperature tolerance.

- Precision Manufacturing: Suitable for various high-precision manufacturing processes, ensuring stable operation of equipment under high-temperature and high-precision conditions.

new material

new material