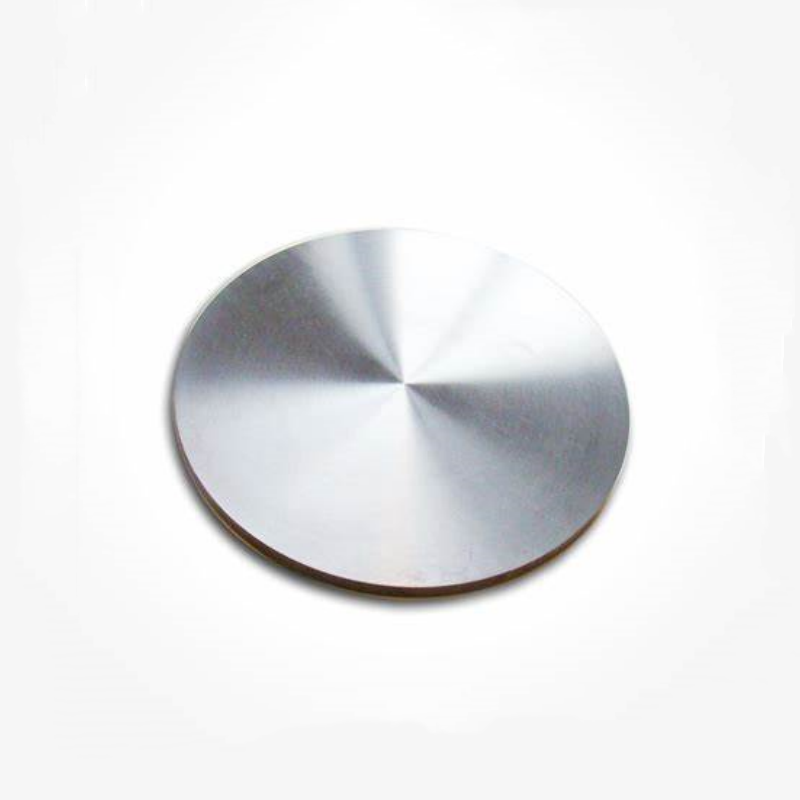

Magnesium-lanthanum-cerium alloy (MgLaCe30) is an advanced metallurgical material designed for superior oxidation resistance, mechanical durability, and thermal stability. The combination of lanthanum and cerium enhances grain refinement, corrosion protection, and structural integrity, making it ideal for aerospace components, industrial machinery, precision manufacturing, and high-temperature applications. Magnesium-lanthanum-cerium alloy plays a crucial role in sustainable engineering, precision metallurgy, and high-performance material solutions.

Product Overview

MgLaCe30 magnesium lanthanum cerium alloy is a high-purity magnesium alloy, enhanced with rare earth elements such as lanthanum (La) and cerium (Ce), specifically designed to improve the metal’s high-temperature resistance, castability, corrosion resistance, and mechanical properties. The alloy, when added prior to casting, effectively reduces oxidation, refines grain structure, enhances the rollability of thin sheets, and minimizes the microbattery effect. This alloy significantly improves casting performance, as well as mechanical and creep properties at high temperatures. It is widely used in fields that demand high-temperature performance, corrosion resistance, and superior mechanical properties.

Key Features

- Enhances high-temperature resistance and corrosion resistance, extending the service life of the alloy.

- Improves casting performance, refines grain structure, and enhances the castability of aluminum alloys.

- Increases the rollability of thin sheets, reduces the microbattery effect, and optimizes processing performance.

- Improves mechanical properties at room temperature, as well as high-temperature mechanical and creep resistance, ensuring stability in high-temperature environments.

- Added prior to pouring to optimize the casting process and improve overall metallic properties.

Applications

- Aerospace:Used for manufacturing high-strength, high-temperature-resistant components for aircraft, particularly in high-temperature environments.

- Automotive Industry:Widely used in the production of automotive engine parts, exhaust systems, and other components requiring high-temperature and corrosion resistance.

- Machinery Manufacturing:Used in manufacturing high-strength, wear-resistant mechanical components, enhancing high-temperature working performance.

- Metallurgical Industry:Applied in high-temperature smelting equipment and related metal casting processes, ensuring alloy stability at high temperatures.

- Electronics Industry:Used for manufacturing high-temperature and corrosion-resistant electronic components, improving the reliability of devices in harsh environments.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform