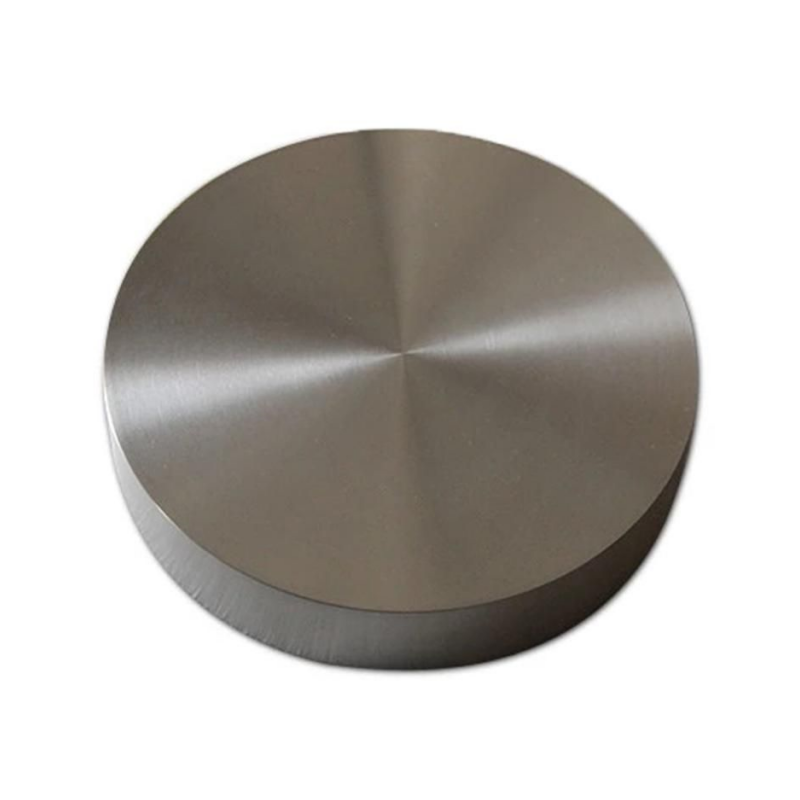

Magnesium-gadolinium alloy (MgGd25) is a high-performance metallurgical material valued for its excellent mechanical strength, corrosion resistance, and thermal stability. The addition of gadolinium enhances the alloy’s structural integrity, oxidation protection, and high-temperature performance, making it an essential material for aerospace engineering, advanced manufacturing, industrial machinery, and specialized electronic applications. Magnesium-gadolinium alloy plays a crucial role in sustainable engineering, precision metallurgy, and high-performance industrial solutions.

Product Overview

MgGd25 magnesium-gadolinium alloy is a high-purity magnesium alloy containing 25% gadolinium. The addition of gadolinium significantly improves the metal’s high-temperature resistance, castability, corrosion resistance, and mechanical properties. Gadolinium enhances the alloy’s oxidation resistance, refines the grain structure, and strengthens high-temperature mechanical properties and creep resistance. Additionally, the alloy improves castability, reduces oxidation, and enhances the rollability of thin sheets.

Key Features

- Enhances high-temperature resistance, corrosion resistance, and creep resistance.

- Improves castability, refines grain structure, and optimizes the casting process.

- Increases the rollability of thin sheets and reduces the microbattery effect.

- Improves high-temperature mechanical performance, ensuring stability in extreme environments.

- Optimizes the alloy’s microstructure, improving mechanical properties.

Applications

- Aerospace:Used to manufacture high-temperature and corrosion-resistant components for aircraft, particularly suitable for extreme temperature conditions.

- Automotive Industry:Widely used in the production of high-temperature and high-stress components such as automotive engines and exhaust systems.

- Machinery Manufacturing:Ideal for manufacturing mechanical parts that require high-temperature and corrosion resistance, extending service life.

- Metallurgical Industry:Applied in high-temperature smelting equipment and casting processes, optimizing the casting performance of aluminum alloys.

- Electronics Industry:Enhances the reliability and service life of electronic devices in high-temperature and corrosion-resistant environments.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform