Medium-temperature zinc oxide desulfurizer is a high-performance catalytic material designed for the selective removal of hydrogen sulfide (H₂S) and other sulfur-containing impurities from industrial gas streams under moderate temperature conditions. Engineered with optimized zinc oxide formulations, it enhances adsorption efficiency, improves impurity elimination, and ensures prolonged operational stability for industrial applications. This catalyst plays a critical role in gas refining, petrochemical processing, and syngas purification, delivering reliable performance for sustainable sulfur removal.

Product Overview:

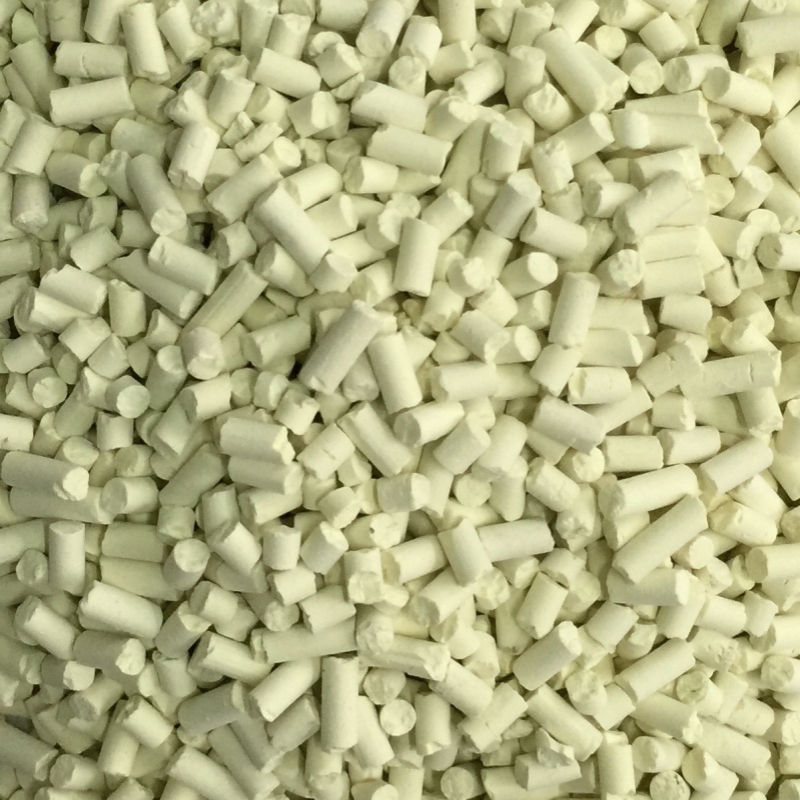

The Medium-Temperature Zinc Oxide Desulfurizer is a highly efficient desulfurization catalyst primarily used for removing inorganic sulfur from coal gas after hydrotreating catalysts, protecting conversion and synthesis catalysts. This catalyst is mainly composed of zinc oxide and effectively adsorbs and removes sulfur compounds from coal gas, offering high stability and efficiency during gas treatment processes.

Key Features:

- High Zinc Oxide Content:Zinc oxide content ≥90%, ensuring excellent desulfurization performance.

- Good Thermal Stability:Operates efficiently within a temperature range of 200–450°C, suitable for medium-temperature conditions.

- High Sulfur Absorption Capacity:Efficiently removes sulfur compounds from coal gas under various temperature conditions, ensuring effective gas purification.

- Excellent Mechanical Strength:High crush strength (≥60N/cm), ensuring the catalyst's integrity during use and preventing breakage.

- Low Attrition:Attrition rate ≤3%, extending the catalyst's service life.

Applications:

- Coal Gas Desulfurization:Widely used for removing inorganic sulfur from coal gas to protect hydrotreating, conversion, and synthesis catalysts.

- Industrial Gas Purification:Can be applied in the treatment of sulfur compounds in various industrial gases, including chemical, energy, and coal chemical industries.

- Catalyst Protection:Plays a crucial role in protecting downstream catalysts in synthesis gas treatment, preventing catalyst poisoning, and improving process safety and stability.

new material

new material