Industrial-grade 3A molecular sieve offers optimized adsorption properties, superior moisture removal, and enhanced thermal stability. Designed for gas drying, dehydration processes, and industrial applications, it ensures efficient moisture control, extended durability, and high adaptability.

Product Overview

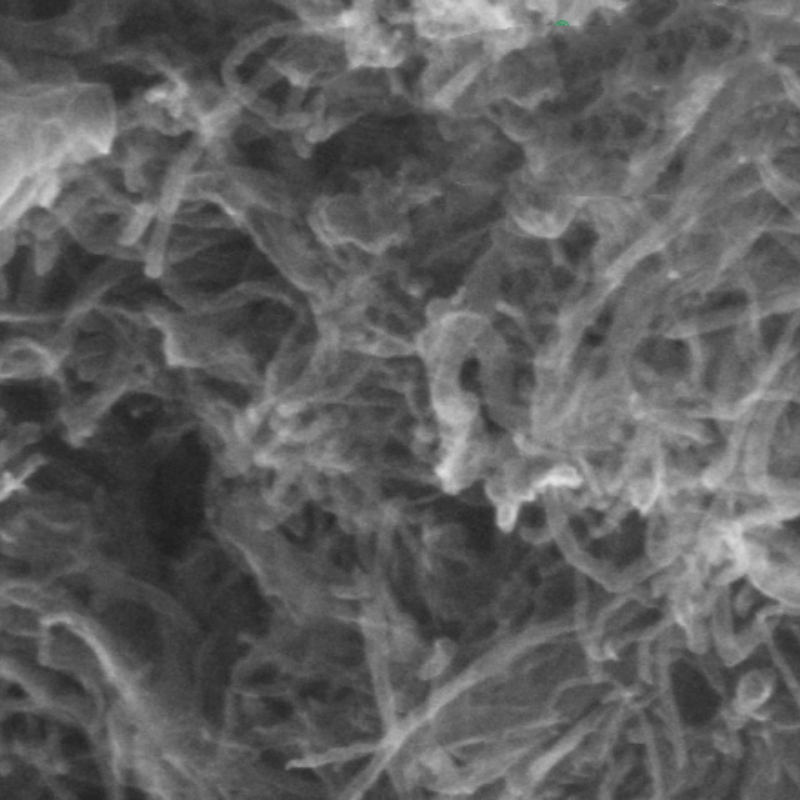

The industrial-grade 3A molecular sieve is a type of molecular sieve material with a specific pore structure designed primarily for adsorption and drying applications. Its 3A pore size is specially engineered to efficiently adsorb moisture, while also offering excellent chemical and thermal stability, making it suitable for a variety of harsh industrial environments.

Product Features

- Efficient Drying: Effectively adsorbs moisture, widely used for drying various gases.

- Excellent Chemical Stability: Maintains stable performance in diverse chemical environments.

- High Thermal Stability: Capable of withstanding high-temperature working conditions, ideal for high-temperature applications.

Applications

- Petroleum and Chemical Industry: Used for drying petroleum cracking gas, olefins, refinery gas, and oil field gas, ensuring gas purity.

- Pharmaceutical Industry: Applied in the drying process of pharmaceutical production to ensure product quality.

- Insulated Glass Industry: Used in the drying process during insulated glass manufacturing to maintain the glass's excellent properties.

- Other Industrial Drying: Serves as a drying agent in various industrial applications, catering to different needs.

| Technical Parameters | Values |

| State | Yellow spherical |

| Pore Size (nm) | ~0.3 |

| Si/Al Ratio | ~2 |

| Bulk Density (g/ml) | 0.75 |

| Residual Moisture Content (wt%) | 0.09 |

| Diameter (mm) | 3~5 |

| Na2O wt% | 6.8 |

new material

new material