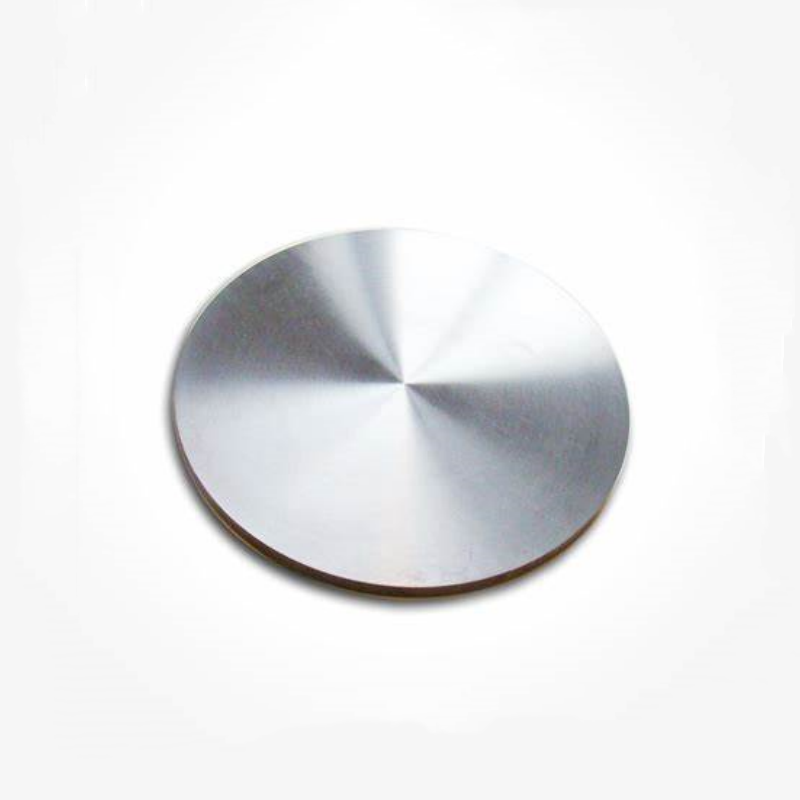

Inconel 825 Alloy is a high-performance nickel-iron-chromium alloy known for its excellent resistance to both oxidizing and reducing acids, stress-corrosion cracking, and pitting. This alloy is widely used in various industries, including chemical processing, oil and gas, and marine, where it serves in critical components exposed to demanding environments. Its unique properties make it ideal for applications requiring exceptional corrosion resistance, durability, and reliability.

Product Overview

Inconel 825 is a corrosion-resistant alloy with a high nickel content, specifically designed to resist stress corrosion cracking. It exhibits excellent resistance to a variety of corrosive environments, particularly in acidic conditions, seawater, and under high-temperature and high-pressure applications. This alloy is widely used in petrochemical, marine engineering, and other harsh environments, providing exceptional overall performance and effectively combating various corrosive agents.

Key Features

- Excellent Corrosion Resistance: Outstanding resistance to a wide range of acidic, alkaline solutions, and chloride-containing media.

- High Nickel Content: Offers superior stress corrosion cracking resistance, making it ideal for highly corrosive environments.

- High-Temperature Resistance: Maintains good mechanical properties and chemical stability even in high-temperature conditions.

Applications

- Chemical Industry: Used in heating tubes, containers, baskets, and chains in sulfuric acid pickling plants.

- Marine Engineering: Widely used in seawater cooling heat exchangers, marine product pipeline systems, and acid gas environment pipelines.

- Phosphoric Acid Production: Used as material for heat exchangers, evaporators, and wash pipelines in phosphoric acid production.

- Petroleum Refining: Employed in air heat exchangers and other petroleum refining equipment.

- Food Engineering and Chemical Processes: Used as corrosion-resistant material in food processing and chemical applications.

- Oxygen Environments: Applied in oxygen-rich environments as a fire-resistant alloy.

| Ni(+Co) | Mo | Mn | Fe | Cu | S | Cr |

| 38.0~46.0 | 2.5~3.5 | ≤1.0 | ≥22.0 | 1.5~3.0 | ≤0.03 | 19.5~23.5 |

| C | Si | Al | Ti | |||

| ≤0.05 | ≤0.5 | ≤0.2 | 0.6~1.2 |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform