Inconel 625 Alloy is a high-performance nickel-chromium-molybdenum alloy known for its exceptional resistance to oxidation and corrosion, high strength, and excellent fatigue and thermal fatigue properties. This alloy is widely used in various industries, including aerospace, marine, and chemical processing, where it serves in critical components exposed to demanding environments. Its unique properties make it ideal for applications requiring durability, reliability, and high performance.

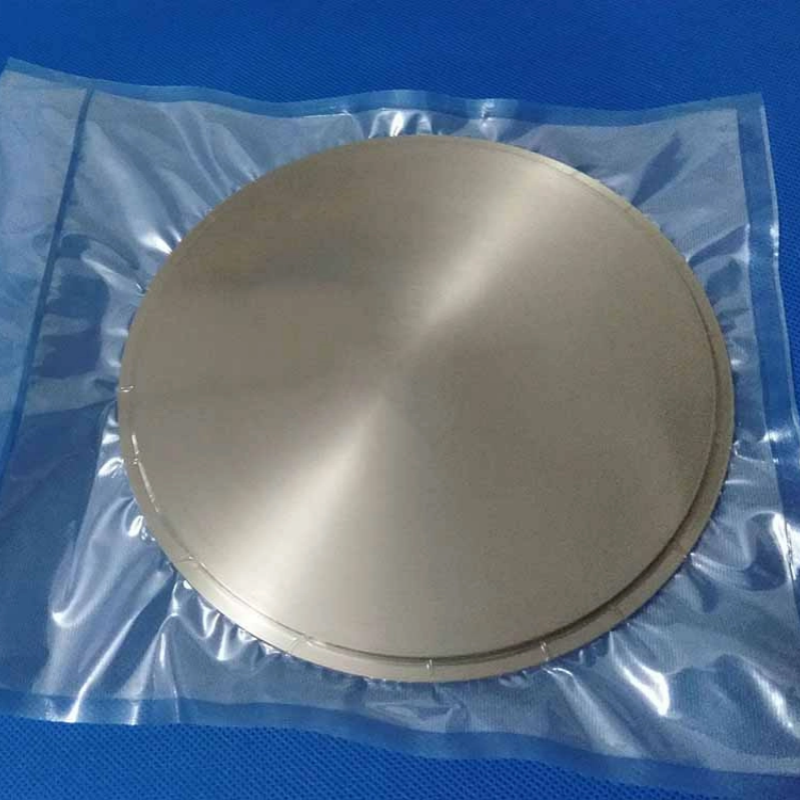

Product Overview

Inconel 625 is a nickel-chromium-molybdenum-based high-performance alloy known for its outstanding corrosion resistance, particularly in chloride environments. This alloy effectively prevents pitting, crevice corrosion, intergranular corrosion, and erosion, making it an ideal material for use in highly corrosive environments such as chemical processing, petrochemical, metallurgy, and environmental protection industries.

Key Features

- Exceptional Corrosion Resistance: Inconel 625 demonstrates strong resistance to corrosive media in both oxidizing and reducing environments, particularly in chloride environments, preventing pitting and crevice corrosion.

- Excellent Acid Resistance: The alloy offers strong resistance to various inorganic acids, including nitric acid, phosphoric acid, hydrochloric acid, sulfuric acid, and more.

- Stress Corrosion Cracking Resistance: Inconel 625 is resistant to stress corrosion cracking, particularly from chloride-induced stress, ensuring long-term stability in harsh environments.

- Good Workability and Weldability: The alloy exhibits good workability and weldability with minimal sensitivity to cracking after welding.

Applications

- Organic Chemical Processing: Used for components in chemical processes that involve chlorides, especially in applications using acidic chloride catalysts.

- Pulp and Paper Industry: Ideal for manufacturing digester and bleaching equipment.

- Flue Gas Desulfurization Systems: Widely used in scrubbers, reheaters, gas intake baffles, fans, stirrers, and guide vanes in desulfurization systems.

- Acid Gas Environments: Applied in equipment and components used in environments containing acid gases.

- Chemical Reactors: Suitable for manufacturing components in reactors, such as acetic acid and acetic anhydride reactors.

- Sulfuric Acid Condensers: Used in the production of corrosion-resistant parts for sulfuric acid condensers.

| Alloy Grade | Inconel 625 | |

| % | Min | Max |

| Ni | Balance | 69 |

| Cr | 20 | 23 |

| Mo | 8 | 10 |

| Nb | 3.15 | 4.15 |

| Fe | 5 | |

| Al | 0.4 | |

| Ti | 0.4 | |

| C | 0.1 | |

| Mn | 0.5 | |

| Si | 0.5 | |

| Co | 1 | |

| P | 0.015 | |

| S | 0.015 | |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform