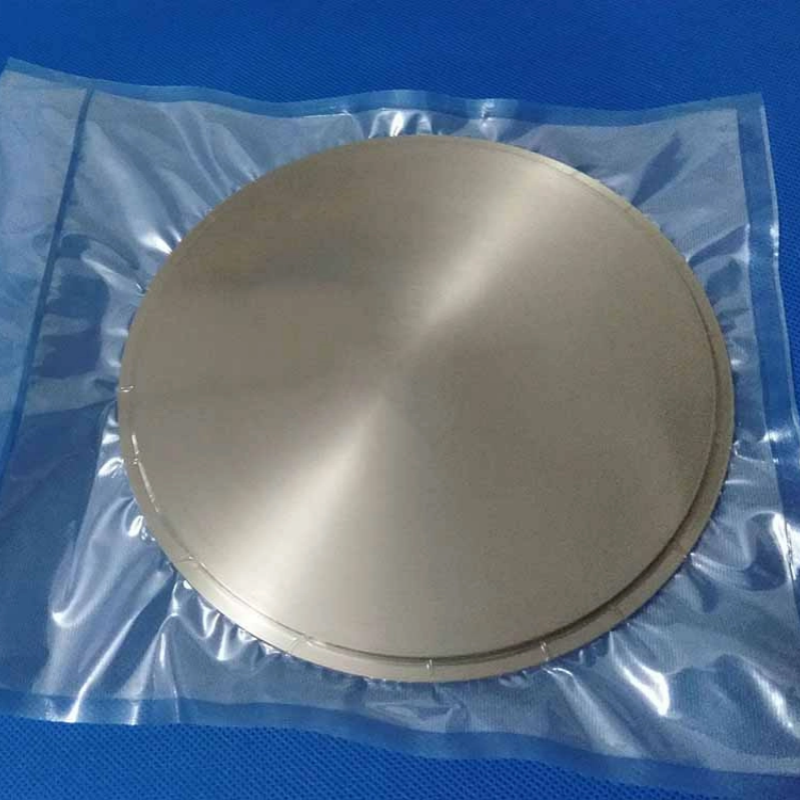

Inconel 600 Alloy is a high-performance nickel-chromium-iron alloy known for its excellent resistance to corrosion and heat, high strength, and good workability. This alloy is widely used in various industries, including chemical processing, aerospace, and marine, where it serves in critical components exposed to demanding environments. Its unique properties make it ideal for applications requiring durability, reliability, and high performance.

Product Overview

Inconel 600 is a nickel-chromium-iron-based solid solution strengthened alloy, known for its exceptional high-temperature corrosion resistance and oxidation resistance. The alloy exhibits good thermal strength and high plasticity below 700°C, making it ideal for use in high-temperature and highly corrosive environments. Inconel 600 offers excellent cold and hot working capabilities, as well as excellent weldability, making it a preferred material in many industrial applications.

Key Features

- High-Temperature Corrosion Resistance: Inconel 600 demonstrates outstanding resistance to high-temperature and oxidative environments.

- High Plasticity and Thermal Strength: The alloy maintains good thermal strength and high plasticity under high-temperature conditions, suitable for extreme working conditions.

- Excellent Machinability: The alloy is easy to work with and can be welded or subjected to other processing methods.

- Wide Range of Corrosion Resistance: Resistant to various corrosive environments, including chlorine, hydrogen fluoride, and ammonia gas.

Applications

- Thermocouple Sheaths: Used in thermocouple sheaths exposed to corrosive atmospheres.

- Chlorine Monomer Production: Resistant to chlorine, hydrogen chloride, oxidation, and carbonization corrosion, ideal for chlorine monomer production.

- Uranium Oxidation to Hexafluoride: Withstands hydrogen fluoride corrosion, suitable for uranium oxidation processes.

- Corrosive Alkali Metal Production: Ideal for environments containing sulfur compounds, offering excellent corrosion resistance.

- Titanium Dioxide Production: Suitable for chlorine-based titanium dioxide production processes.

- Organic or Inorganic Chlorides and Fluorides: Resistant to chlorine and fluorine gas corrosion, widely used in chemical production.

- Nuclear Reactors: Used for critical components in nuclear reactors.

- Heat Treatment Furnaces: Used in heat treatment furnace components for carburizing and nitriding atmospheres.

- Petrochemical Catalyst Regenerators: Recommended for use in petrochemical production environments above 700°C to provide extended service life.

| Alloy grade | Inconel 600 Alloy | |

| Min. | Max. | |

| N | 72 | |

| Ni | 72 | |

| C | 14 | 17 |

| Fe | 6 | 10 |

| C | 0.15 | |

| Mn | 1 | |

| Si | 0.5 | |

| Cu | 0.5 | |

| Al | ||

| Ti | ||

| B | ||

| Р | ||

| S | 0.015 | |

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform