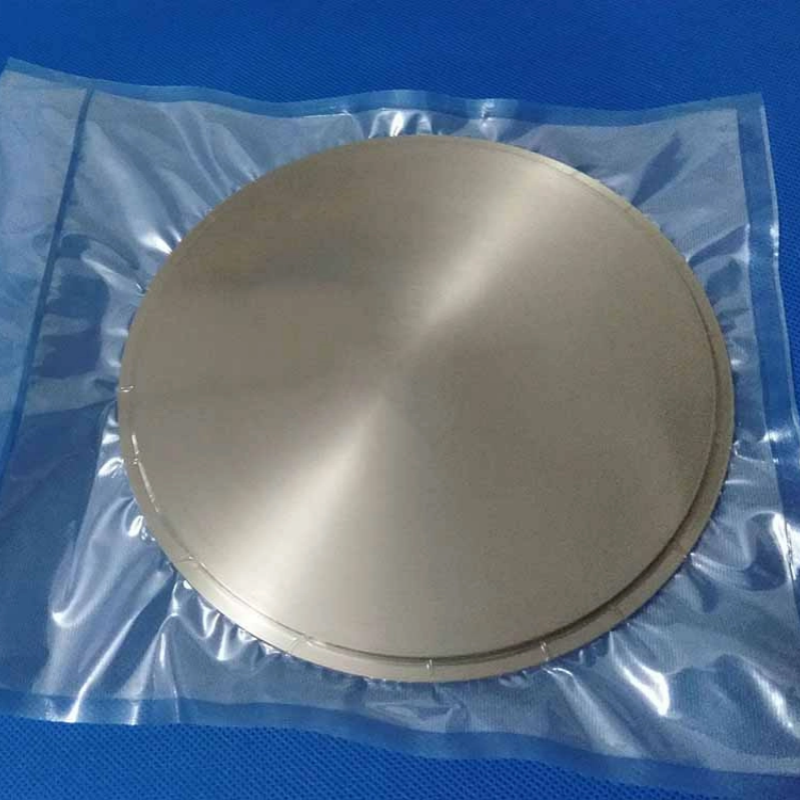

High-Temperature Alloy GH4049 is a nickel-based superalloy that is widely utilized in aerospace, power generation, and high-temperature industrial applications. It is praised for its excellent high-temperature performance, superior oxidation resistance, and exceptional mechanical strength, making it ideal for turbine components, heat exchangers, and combustion chambers used in extreme environments.

Product Overview

GH4049 is a nickel-based high-temperature alloy specifically designed for applications requiring exceptional resistance to deformation at high temperatures. The alloy exhibits outstanding oxidation resistance below 1000°C and high-temperature strength below 950°C. It is widely used in aerospace engines, especially for turbine blades and other critical components exposed to high heat and pressure conditions, offering long-term stability and durability.

Key Features

- Strong Oxidation Resistance:GH4049 shows excellent oxidation resistance at elevated temperatures, particularly effective below 1000°C.

- Superior High-Temperature Strength:The alloy maintains high strength below 950°C, making it suitable for high-temperature applications that demand both durability and strength.

- Exceptional Durability:Ideal for components that operate in high-temperature environments, such as turbine blades and structural parts in aerospace engines, where durability and resistance to thermal stresses are essential.

- Excellent Heat Treatment Performance:After standard heat treatment, GH4049 exhibits superior microstructure, improving high-temperature strength and toughness, allowing it to perform reliably under demanding conditions.

Applications

- Aerospace Industry:GH4049 is used extensively in the aerospace industry for turbine blades, turbine casings, and other high-temperature structural components that require high strength, oxidation resistance, and long-term durability in harsh environments.

- High-Temperature Load-Bearing Parts:Suitable for other high-temperature environments where components are subject to significant thermal stress, requiring excellent oxidation resistance, strength, and durability.

- High-Temperature Engineering Applications:The alloy is widely applied in industrial equipment and engineering materials that need stability, oxidation resistance, and high-temperature performance.

| Alloy | C | Cr | Co | W | Mo | Al | Ti | Fe | V | Ni | |

| GH4049 | 0.04-0.10 | 9.5~11.0 | 14.0-16.0 | 5.00-6.00 | 4.50-5.50 | 3.7-44 | 141.9 | 150 | 0.2~0.5 | Remaining | |

| 0.04-0.10 | 9.0~12.0 | 12.0~16.0 | 4.50-6.50 | 4.0-6.0 | 3.6-4.5 | 14-2.0 | 45 | 0.2-0.8 | Remaining | ||

| B | Ce | Mo | Si | P | S | Cu | Bi | Sn | Sb | As | Pb |

| Not more than | |||||||||||

| 0.025 | 0.02 | 0.5 | 0.5o | 0.01 | 0.01 | 0.07 | 0.0001 | 0.0012 | 0.0025 | 0.0025 | o.001 |

| 0.02 | 0.02 | 0.5 | 0.5 | 0.015 | 0.o10 | 0.07 | |||||

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform