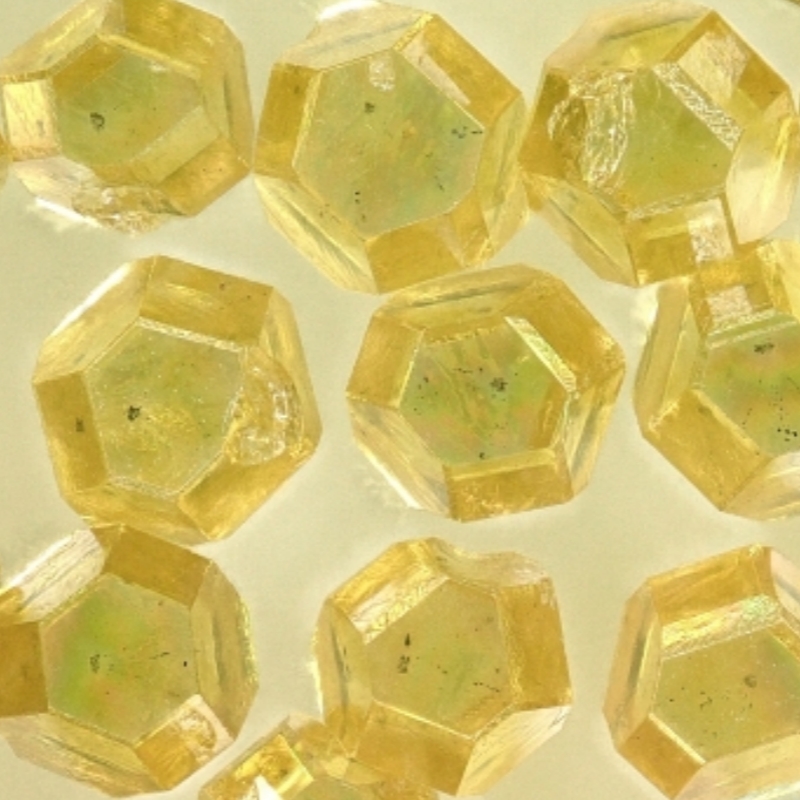

High-strength, high-thermal stability diamond material (WBD2190) is an advanced synthetic diamond designed for extreme durability, exceptional heat resistance, and superior wear performance. Engineered with an optimized crystalline structure, WBD2190 maintains outstanding mechanical integrity under high temperatures and heavy-load industrial applications. This material is widely used in aerospace components, precision machining tools, semiconductor substrates, and high-performance cutting applications, ensuring reliability in demanding environments.

Product Overview

WBD2190 is a high-strength diamond cutting material with excellent thermal stability. It features consistent crystal form and color, providing outstanding performance when cutting hard stones and concrete. Its regular crystalline structure and excellent transparency make it particularly suitable for tool manufacturing in harsh conditions.

Features

- Consistent Crystal Form and Color: Ensures stability and consistency during the cutting process, improving tool life and processing efficiency.

- Regular Crystal Structure: The regular crystalline form provides uniform cutting performance, reducing tool wear.

- Good Transparency: Excellent transparency allows for more precise cutting, ideal for precision machining.

- High Strength: High strength makes it suitable for high-load cutting operations, ensuring stability under high-stress conditions.

- Excellent Thermal Stability: The exceptional thermal stability makes it suitable for cutting and drilling in high-temperature environments.

Applications

- Hard Stone Cutting: Widely used for cutting various hard stones, ensuring processing precision and quality.

- Concrete Cutting Tools: Suitable for cutting tools used in concrete and other construction materials, improving tool performance and efficiency.

- Geological Engineering Drill Bits: Used in various geological engineering drill bits, meeting the demands of rigorous drilling operations.

new material

new material