High-purity alumina additive for lithium battery separator materials provides optimized thermal stability, superior ion conductivity, and enhanced mechanical reinforcement. Designed for advanced energy storage applications, it ensures efficient charge transport, extended lifespan, and high-performance adaptability.

Product Overview

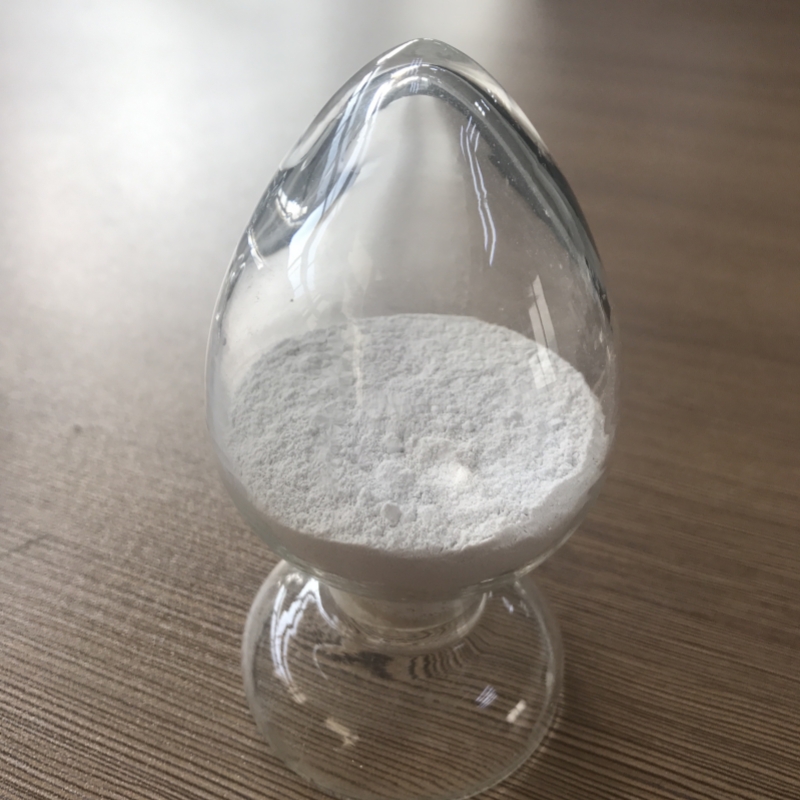

High purity alumina additive for lithium battery separator materials is a premium alumina powder specifically designed to modify the separator materials in lithium batteries. This high-purity alumina enhances the mechanical strength, thermal stability, and electrolyte corrosion resistance of the separator, thereby improving the battery's safety and performance. As an additive, it has excellent dispersion properties, allowing it to integrate evenly into separator materials, ensuring stable performance improvements.

Features

- Increased Mechanical Strength: Enhances the separator's tear resistance and puncture resistance, ensuring stability under high-pressure conditions.

- Improved Thermal Stability: Optimizes the battery's performance under high-temperature conditions, preventing safety issues caused by thermal runaway.

- Enhanced Corrosion Resistance: Improves the stability of the separator material in the electrolyte, extending battery life.

- Excellent Dispersion: Nanometer-sized particles can be uniformly dispersed, ensuring consistent and stable modification effects.

- High Purity: The high purity of alumina minimizes the impact of impurities, ensuring the enhancement of battery performance.

Applications

- Lithium Battery Separator Materials: As an additive to improve the mechanical strength, thermal stability, and electrolyte compatibility of lithium battery separators.

- Other Battery Materials: Can also be used to modify separators or electrode materials in other types of batteries, enhancing overall battery performance.

| Property | LA43G | LA35G | LA34G |

| Average Particle Size (D50) | 0.3-0.5μm | 0.5-1.0μm | 0.4-0.7μm |

| Al₂O₃ Purity | 99.99% | 99.90% | 99.90% |

| Specific Surface Area (m²/g) | 6~15 | 4~8 | 8~10 |

new material

new material