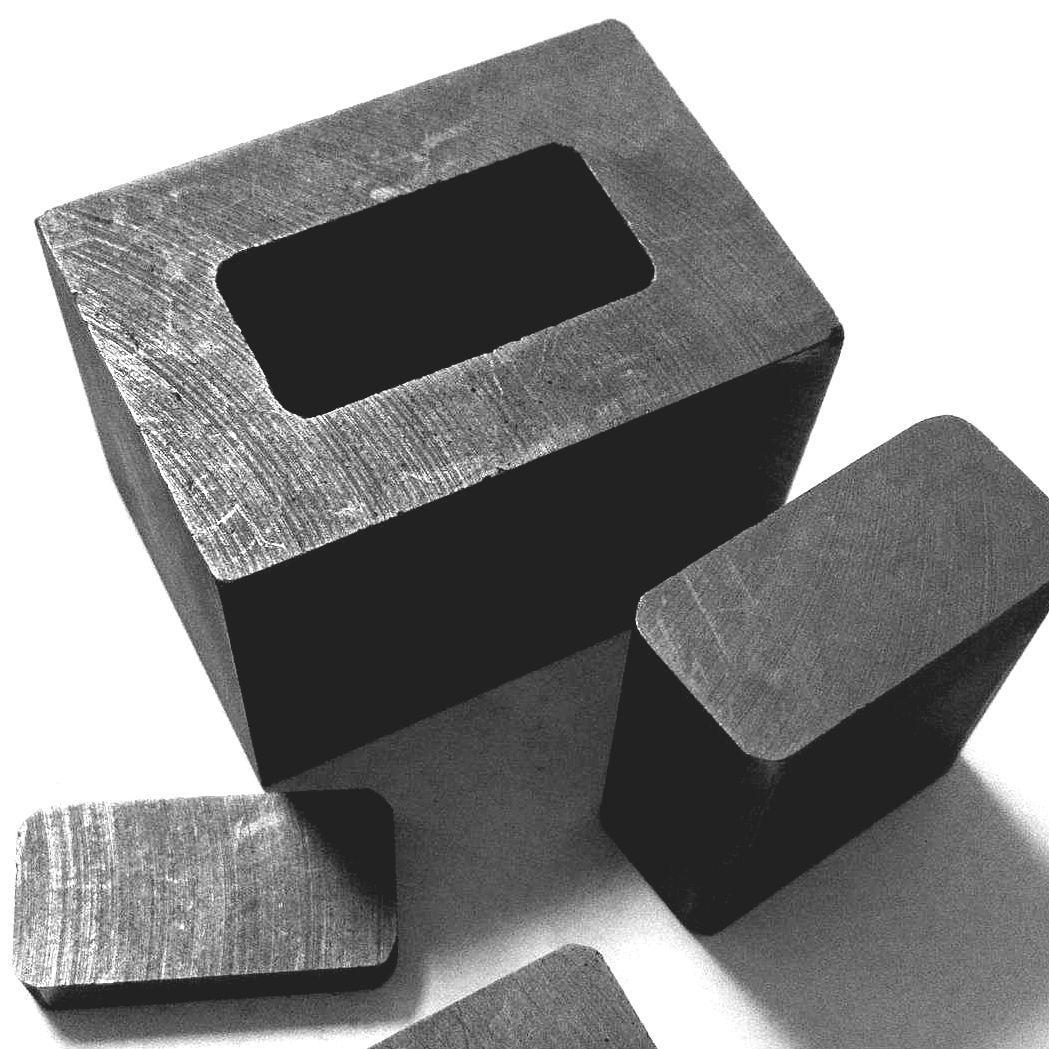

Graphite molds are precision-engineered carbon components designed for industrial applications requiring high thermal stability, superior wear resistance, and excellent chemical inertness. Manufactured using high-purity graphite, these molds offer optimized structural integrity, minimal thermal expansion, and extended service life. They are widely used in metal casting, glass production, semiconductor fabrication, and high-temperature furnace applications, ensuring efficient material shaping and reliable performance under extreme conditions.

Product Overview

Graphite molds are essential equipment in industrial manufacturing, widely used in processes such as stamping, forging, die casting, extrusion, and plastic injection molding. Due to its excellent physical and chemical properties, graphite is the preferred material for mold production. Its exceptional thermal conductivity, thermal stability, corrosion resistance, and good machinability make graphite molds crucial in modern industrial production. Graphite molds can be customized to meet specific product shapes and precision requirements, serving a wide range of industrial manufacturing and precision machining needs.

Key Features

- Excellent Thermal and Electrical Conductivity: Graphite has outstanding heat and electrical conductivity, allowing rapid heat transfer and reducing heating loss in molds.

- Low Thermal Expansion and Resistance to Thermal Shock: Graphite molds have a low coefficient of linear expansion, maintaining shape stability even under high temperatures.

- Chemical Corrosion Resistance: Graphite offers high resistance to corrosion from most metals, making it highly durable in harsh environments.

- Increased Strength at High Temperatures: Graphite molds experience enhanced strength at elevated temperatures, ensuring stability under extreme conditions.

- Easy to Machine: Graphite molds are easy to process and can be shaped into complex, precise molds that meet diverse industrial requirements.

Applications

- Non-Ferrous Metal Casting: Used extensively in continuous and semi-continuous casting of non-ferrous metals like copper and aluminum, improving casting precision and surface quality.

- Pressure Die Casting: Graphite molds are used in pressure die casting of non-ferrous metals, especially for zinc and copper alloys, making them suitable for precision manufacturing of automotive parts.

- Centrifugal Casting: Graphite molds excel in centrifugal casting, ideal for producing bronze bushings and similar components.

- Hot Press Molding: Used in the sintering of hard metals, graphite molds provide stable pressure and temperature at high temperatures, ensuring the density and integrity of sintered materials.

- Glass Molding: In glass manufacturing, graphite molds are used to create shaped glass bottles, such as glass tubes and bent pipes.

- Diamond Sintering: In diamond tool manufacturing, graphite molds play a dual role as both heat-generating components and supporting molds, ensuring dimensional accuracy and performance of the tools.

- Electrical Discharge Machining (EDM): Graphite molds are widely used in EDM for their rapid discharge, low wear, and long lifespan, making them ideal for industries such as home appliances, automotive, electromechanics, and aerospace.

new material

new material