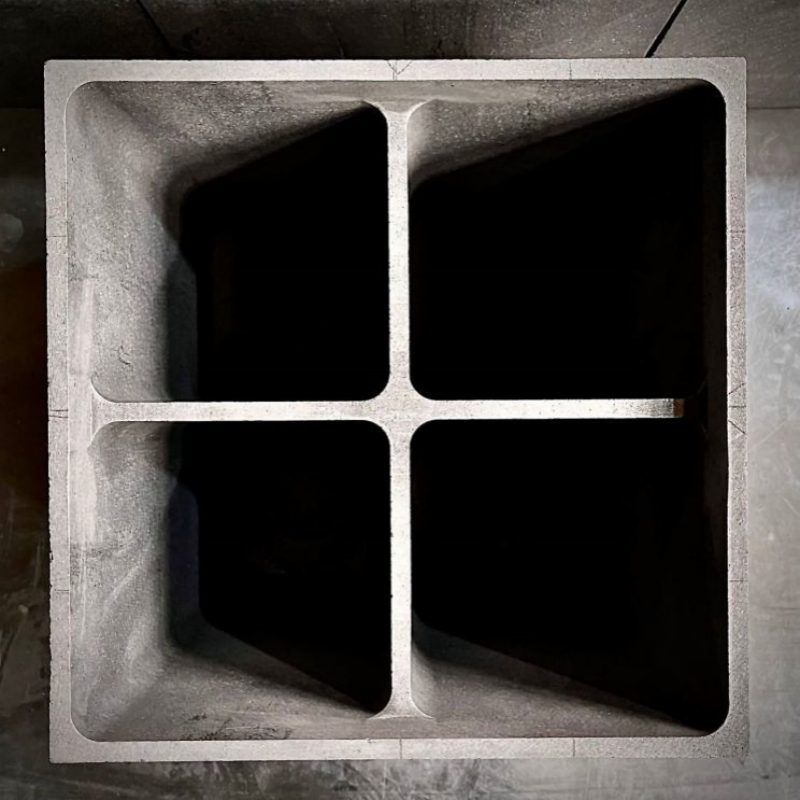

Graphite crucibles are high-performance carbon containers designed for industrial applications requiring superior thermal resistance, high mechanical strength, and excellent chemical stability. Manufactured from high-purity graphite, these crucibles provide optimized heat retention, minimal contamination risk, and extended service life in extreme temperature environments. They are widely used in metal casting, semiconductor processing, laboratory research, and high-temperature furnace applications, ensuring reliable performance in demanding conditions.

Product Overview

The Graphite Crucible is made from high-purity graphite material, specifically designed for high-temperature sintering, heat treatment, and other processes in lithium battery electrode material manufacturing. Its exceptional high-temperature resistance and oxidation resistance make it an indispensable tool in the battery production process. The crucible is also highly chemically stable and has a low expansion coefficient, making it ideal for the synthesis and processing of various lithium battery cathodes and anodes.

Key Features

- Exceptional High-Temperature Performance: The crucible can maintain stability at high temperatures, capable of withstanding high sintering temperatures during the battery manufacturing process.

- Chemical Stability: The graphite crucible has excellent corrosion resistance, making it suitable for a wide range of chemical reaction environments without degradation.

- High Dimensional Stability: The product retains its shape and size during high-temperature treatment, ensuring it doesn’t deform or get damaged during the processing stages.

- Low Expansion Coefficient: The low thermal expansion of graphite ensures minimal deformation in high-temperature environments, stabilizing the sintering process.

- High-Purity Material: Made from high-purity graphite, the crucible ensures excellent thermal conductivity under high temperatures, enhancing the efficiency of the sintering or heating process.

Applications

- Lithium Battery Industry: Widely used in the high-temperature sintering and treatment of lithium battery cathode and anode materials.

- Electronics Industry: Serves as a high-temperature container for sintering electronic components and other delicate materials.

- Materials Processing: Used for the high-temperature treatment, sintering, and heat processing of metals, ceramics, and other materials.

- Chemical Industry: Applied in chemical reaction processes that require high-temperature treatment, thanks to its excellent chemical stability.

new material

new material