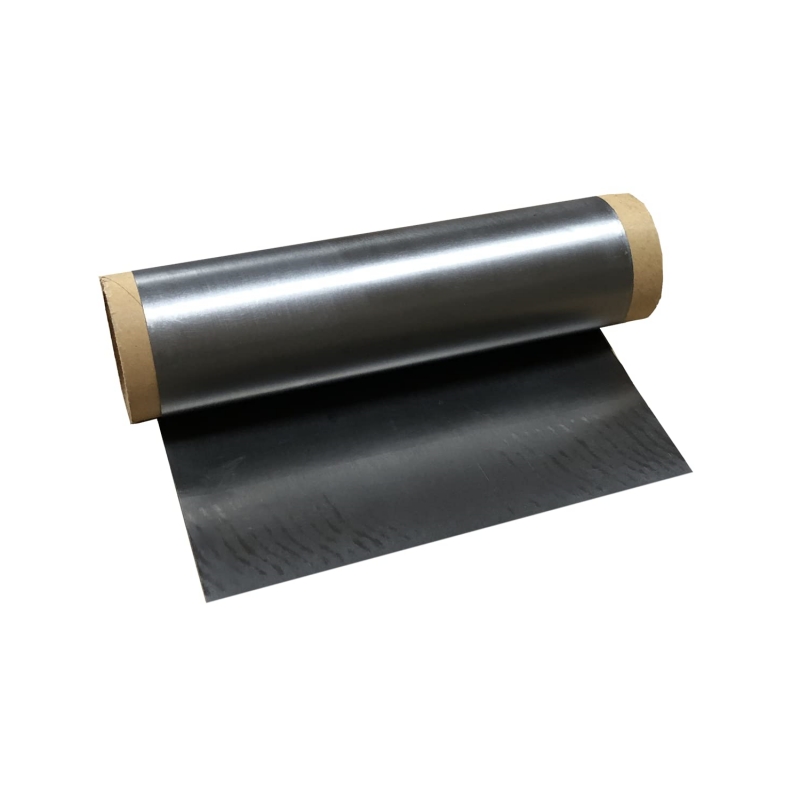

Environmental high-purity graphite thermal conductive film, flexible graphite sheets, and flexible graphite paper are advanced carbon-based materials designed for thermal management, electrical conductivity, and industrial applications. Manufactured from natural graphite through precision processing techniques, these materials exhibit exceptional heat dissipation, chemical resistance, and mechanical flexibility. Widely used in electronics cooling systems, battery thermal regulation, aerospace components, industrial insulation, and sealing solutions, they ensure reliable performance in demanding environments requiring efficient heat control and structural adaptability.

Product Overview

Environmental high purity graphite thermal conductive film, flexible graphite sheets, and flexible graphite paper are made from natural high-purity flake graphite through chemical treatment and high-temperature processing. These products are molded and rolled without any binders, ensuring superior performance. They excel in sealing capabilities under extreme conditions, offering long service life, low maintenance costs, and significant improvements in heat conduction efficiency. These materials are widely used in industries and fields that require both thermal conduction and sealing properties.

Key Features

- Excellent Thermal Conductivity: Provides superior heat conduction, making it ideal for high-efficiency heat dissipation and thermal management applications.

- Strong Electrical Conductivity: Suitable for use as a conductive material in batteries and electronic products.

- High and Low Temperature Resistance: Able to withstand extreme temperature fluctuations, ensuring stable performance over the long term.

- Corrosion Resistance: Resistant to a wide range of corrosive media, making it suitable for use in harsh environmental conditions.

- Self-Lubricating Properties: Reduces friction and improves equipment operational efficiency and longevity.

- Flexibility and Resilience: Offers good flexibility and rebound ability, making it adaptable to various installation requirements.

Applications

- Electronics Industry: Used in electronic products for heat dissipation and thermal management.

- Battery Industry: Employed as a conductive material in batteries.

- Sealing Applications: Used to create sealing rings, graphite tapes, sealing gaskets, composite sheets, and cylinder gaskets.

- Industrial Sealing: Widely used in dynamic and static sealing applications across industries such as power, petroleum, chemical, instrumentation, and machinery. It is an ideal replacement for traditional sealing materials like rubber, fluoroplastics, and asbestos.

| Item | Technical Index |

| Thickness (mm) | 0.03-1.00 |

| Width (mm) | 1.00-1.30 |

| Length (m) | 1.00-200.00 |

| Density (g/cm³) | 0.70-1.60 |

| Item | Grade A | Grade B | Grade C |

| Carbon Content (%) | 99.5 | 99.3 | 99 |

| Sulfur Content (PPM) | ≤1800 | ≤2000 | ≤2200 |

| Chlorine Content (PPM) | ≤35 | ≤40 | ≤45 |

| Density Tolerance (g/cm³) | ±0.03 | ±0.04 | ±0.05 |

| Thickness Tolerance (mm) | ±0.03 | ±0.04 | ±0.05 |

| Compression Ratio (%) | ≥40 (at density of 1.0g/cm³) | ||

| Rebound Rate (%) | ≥10 (at density of 1.0g/cm³) | ||

| Tensile Strength (MPa) | ≥4.0 | ||

| Operating Temperature (°C) | -200~850 | ||

| Operating Pressure (MPa) | 10 |

new material

new material