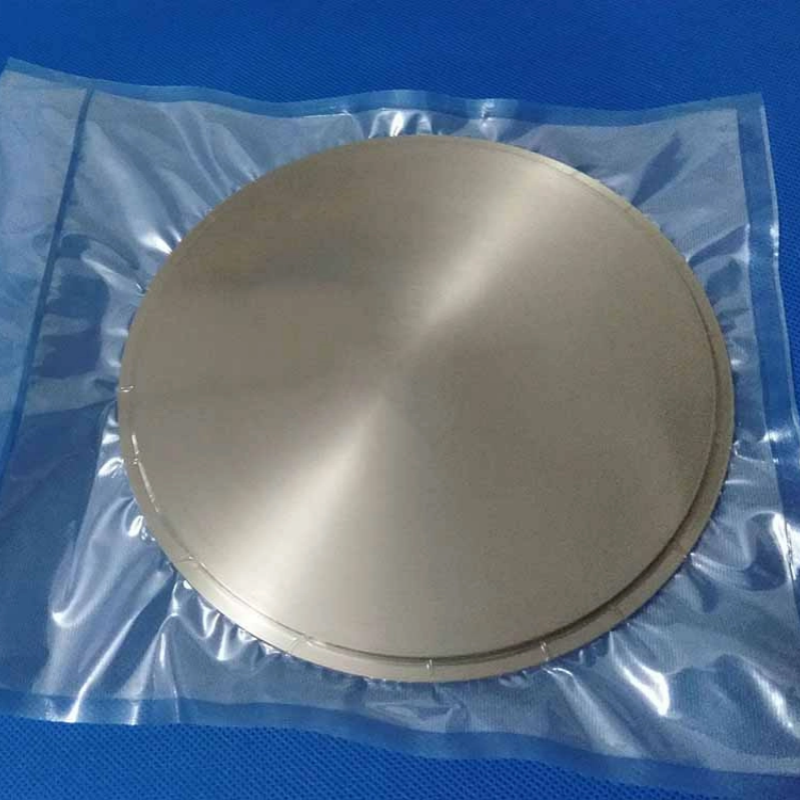

Cobalt-Chromium-Tungsten Alloy Powder is a high-performance alloy powder widely used in aerospace, medical, and industrial applications. Known for its outstanding wear and corrosion resistance, superior mechanical strength, and excellent thermal stability, this powder is ideal for additive manufacturing, metal injection molding, and advanced engineering processes. It is particularly suitable for the production of components such as cutting tools, medical implants, and industrial equipment that require durability and precision.

Product Overview

Cobalt-Chromium-Tungsten Alloy Powder is a metallic alloy composed of cobalt, chromium, and tungsten. It boasts exceptional properties such as high-temperature resistance, wear resistance, and corrosion resistance. This alloy powder is widely used in the manufacturing of components requiring high strength, high wear resistance, and thermal stability. It is commonly applied in aerospace, metallurgy, and mechanical processing industries, particularly in the production of high-end technological equipment.

Product Features

- Outstanding Wear Resistance:Exhibits excellent wear resistance under high pressure and high-temperature environments.

- High-Temperature Stability:Maintains good physical properties even under high-temperature conditions.

- Excellent Corrosion Resistance:Well-suited to harsh environments, offering strong corrosion resistance.

Applications

- Aerospace:Used in the manufacturing of high-temperature components such as engine parts and turbine blades.

- Metallurgy Industry:Suitable for steel refining, casting, and other high-strength equipment manufacturing.

- Mechanical Manufacturing:Used to make high-wear-resistant mechanical components such as gears, bearings, and more.

- High-Temperature Applications:Applied in mechanical processing and equipment manufacturing in extreme high-temperature environments.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform