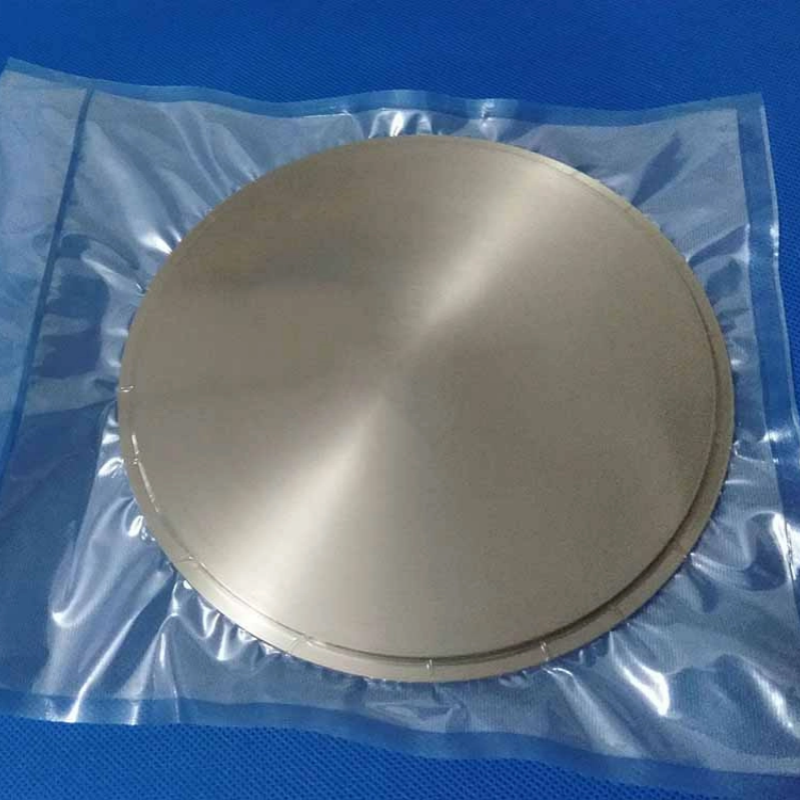

Aluminum-titanium alloy (ALTi5) is a high-performance metallurgical material valued for its superior strength, corrosion resistance, and grain refinement capabilities. It is widely used in aerospace engineering, automotive manufacturing, industrial machinery, and precision casting applications. Due to its ability to improve mechanical properties and thermal stability, aluminum-titanium alloy plays a crucial role in advanced material development, sustainable engineering, and high-performance industrial solutions.

Product Description

The Aluminum-Titanium Alloy (ALTi5) contains 4-6% titanium, which effectively refines the grain structure and enhances the alloy's plasticity. This alloy retains the lightness and excellent processing capabilities of aluminum, while the addition of titanium increases its strength and high-temperature resistance. ALTi5 performs excellently in high-temperature and high-stress environments, making it ideal for aerospace, automotive, and military applications.

Product Features

- Titanium Content (4-6%): Refines the grain structure and improves plasticity, enhancing overall alloy performance.

- Excellent High-Temperature and Corrosion Resistance: Suitable for high-stress and high-temperature environments.

- Good Processability: Can be easily processed into various forms, such as round bars, thin sheets, plates, and particles.

- Strict Control of Composition: Due to the potential for segregation, alloy composition must be strictly controlled during processing.

- Enhanced Strength and Toughness: Increases strength and toughness, ensuring stability in extreme conditions.

Applications

- Aerospace: Used in the manufacture of high-end aerospace components such as aircraft and rocket parts, providing strength and high-temperature resistance.

- Automotive Industry: Ideal for automotive engines and structural components, enhancing fatigue resistance and performance under high temperatures.

- Military: Used in high-strength, lightweight components for military equipment, including weapon systems and aircraft fuselages.

- Marine Industry: Suitable for ship structural components, offering exceptional corrosion resistance and strength.

- Electronics Industry: Applied in the manufacture of electronic product enclosures and components, ensuring heat resistance and structural stability.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform