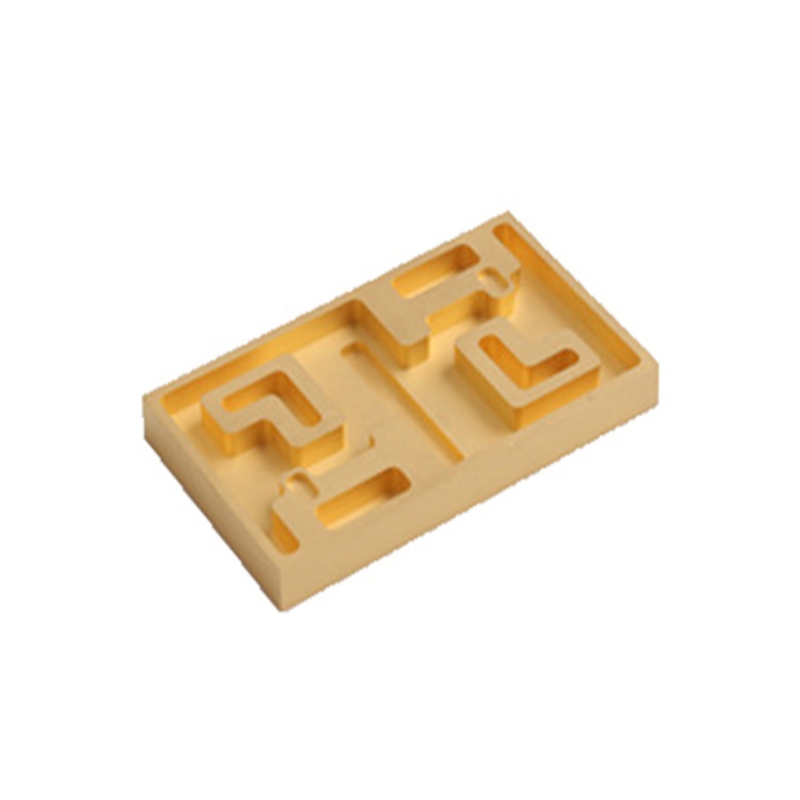

Product Overview

Aluminum Silicon (AlSi) alloy is a lightweight, high thermal conductivity material with a controllable low thermal expansion coefficient. Due to its excellent machining properties, such as ease of CNC machining, electroplating, and welding, AlSi alloy is widely used in the electronic packaging industry, especially for high-temperature, high-power devices with demanding thermal management requirements. It can replace traditional packaging materials like AlSiC, copper tungsten (CuW), and copper molybdenum (CuMo), providing superior performance and cost-efficiency.

Key Features

- Lightweight:With a lower density, it is ideal for applications that require lightweight design solutions.

- Low Thermal Expansion Coefficient:Strong stability, suitable for environments with significant temperature variations.

- High Thermal Conductivity:Effectively improves heat management, essential for high-power devices.

- Excellent Machining Performance:Easily processed with CNC machining, electron beam welding, laser welding, etc.

- Good Electroplating Performance:Can be electroplated with gold, silver, copper, nickel, etc.

- Alternative to Traditional Materials:In certain fields, can replace AlSiC, CuW, CuMo, etc.

Applications

- Electronic Packaging:Widely used for packaging high-power electronic components, providing efficient heat management.

- Thermal Management:Applied in heat sinks and cooling components, especially in high-power, high-temperature environments.

- Automotive and Aerospace:Used as a thermal conductivity material in engine systems and electronic systems.

- Welding and Electroplating:Employed in high-performance welding and electroplating applications.

- Mechanical and Electrical Fields:Used in various mechanical and electronic devices to provide structural stability and thermal conductivity.

new material

new material