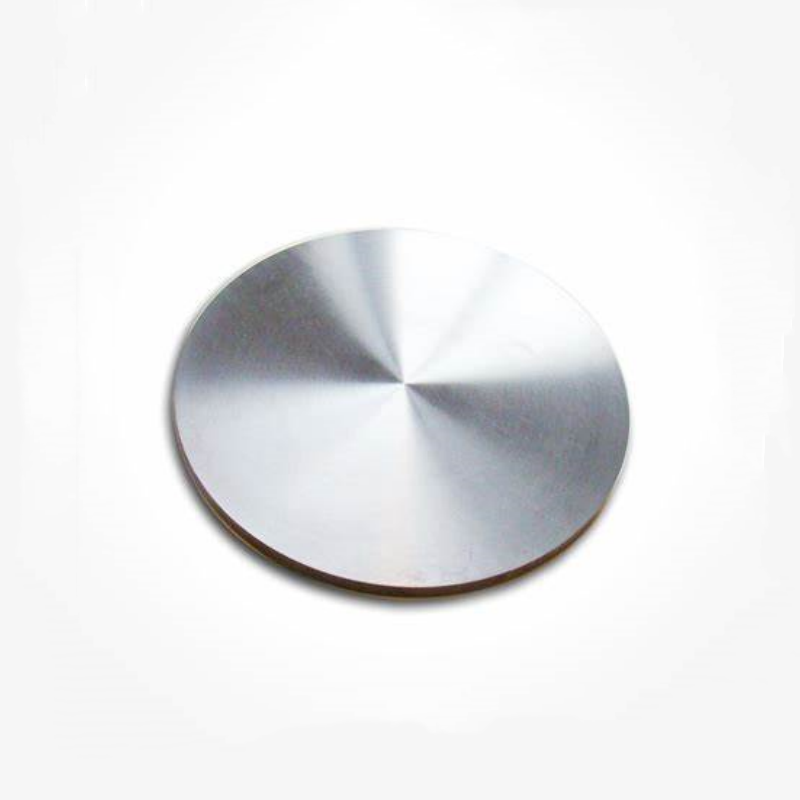

Aluminum-copper alloy (ALCu50) is a high-performance metallurgical material known for its exceptional strength, conductivity, and wear resistance. It is widely used in aerospace engineering, automotive manufacturing, electronic components, and precision industrial applications. The combination of aluminum’s lightweight properties and copper’s enhanced mechanical characteristics makes aluminum-copper alloy a valuable choice in advanced engineering, sustainable manufacturing, and high-performance metallurgy.

Product Description

The Aluminum-Copper Alloy (ALCu50) is an aluminum alloy with a relatively high copper content, typically ranging from 48% to 52%. This alloy exhibits excellent electrical conductivity, thermal conductivity, and corrosion resistance, making it suitable for applications requiring these specific properties. It is characterized by good aluminum-copper composite performance and has some oxidation resistance at high temperatures.

Product Features

- High Copper Content: Provides excellent electrical conductivity and thermal conductivity.

- Good Corrosion Resistance: Suitable for use in harsh environments.

- Brittleness: Relatively brittle, so it must be used with care in specific applications.

- Adjustable Alloy Composition: Can be customized to meet the requirements of various industries.

Applications

- Electronics Industry: Used for manufacturing electronic components, particularly those requiring high electrical conductivity and thermal conductivity.

- Electrical Industry: Serves as a material for high-conductivity components like wires and connectors.

- Aerospace: Used in high-temperature and high-strength environments. However, due to its brittleness, it is typically applied in non-load-bearing structural parts.

- Metallurgical and Chemical Industries: Employed in corrosion-resistant and heat-conductive parts.

Submit Your RequirementsWe will contact you within 24 hours.

WOBO Scientific Research New Materials One-Stop Service Platform

WOBO Scientific Research New Materials One-Stop Service Platform