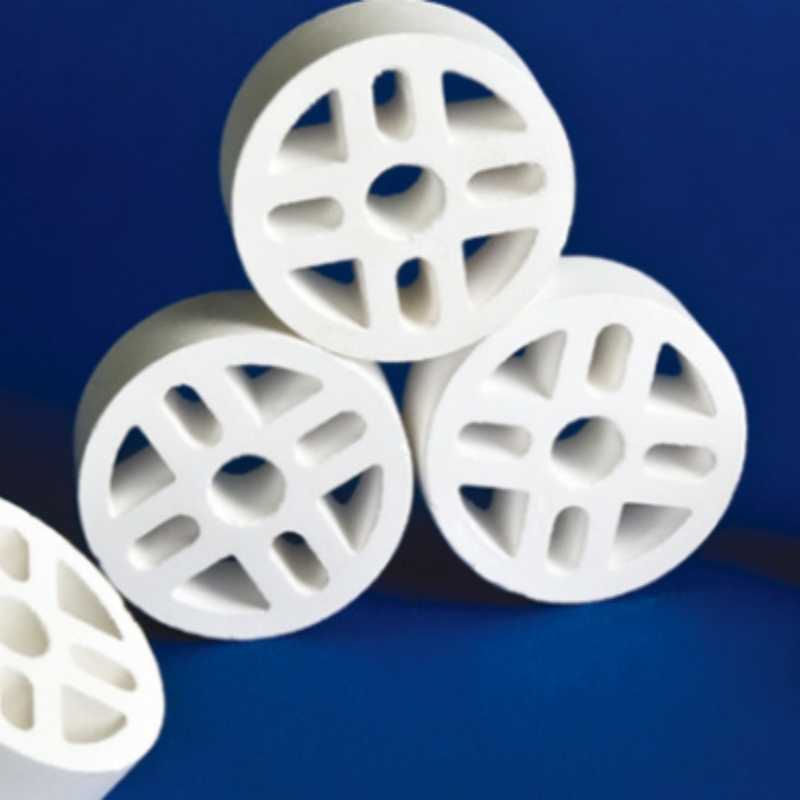

Alumina packing offers exceptional chemical stability, optimized adsorption efficiency, and superior thermal resistance. Designed for industrial filtration and separation applications, it ensures effective material retention, extended lifespan, and high-performance functionality.

Product Overview:

Alumina packing is a high-performance filler material widely used in industries such as chemicals, petroleum, pharmaceuticals, food, electronics, metallurgy, environmental protection, and construction materials. With excellent physical and chemical properties, alumina packing is especially suitable for use in drying towers, absorption towers, cooling towers, and regeneration towers, effectively enhancing reaction and separation efficiency in industrial processes.

Product Features:

- Large Specific Surface Area:The large specific surface area improves reaction or adsorption efficiency, facilitating enhanced process performance.

- High-Temperature Resistance:Designed to operate stably in high-temperature environments without performance degradation due to heat.

- High-Pressure Resistance:With a high compressive strength, it can withstand high-pressure environments commonly found in industrial equipment.

- Excellent Acid and Alkali Corrosion Resistance:Shows exceptional resistance to corrosion, ensuring long-term stability even in strong acidic or alkaline conditions.

- Good Thermal Shock Stability:Able to withstand sudden temperature changes without cracking, making it ideal for dynamic industrial processes.

- Stable Chemical Properties:With stable chemical characteristics, alumina packing is suitable for long-term use in various industrial applications without degradation.

Applications:

- Chemical Industry:Used as packing material in chemical reactors to improve reaction efficiency and enhance mass transfer.

- Metallurgy:In metallurgy, alumina packing serves as an adsorbent and separator in metal smelting processes.

- Coal Gas and Oxygen Production:Commonly used in drying and absorption towers in coal gas and oxygen production equipment.

- Pharmaceutical and Food Industry:Provides stable adsorption and separation in the production processes of pharmaceuticals and food products.

- Electronics Industry:Used as a component in electronic materials, ensuring consistent physical performance.

- Environmental Protection and Construction Materials:Employed in waste gas purification and environmental protection systems for effective gas adsorption and purification.

| Performance Product | 92 Series | 95 Series | 99 Series | 99.5 Series |

| Al2O3 (%) | ≥92 | ≥95 | ≥97 | ≥99 |

| SiO2 | ≤6 | ≤2 | ≤0.2 | ≤0.15 |

| Water Absorption (%) | ≤3 | ≤3 | 4.5328 | 4.5328 |

| Compressive Strength (Φ60mm) | ≥11 (Kn/particle) | ≥13 (Kn/particle) | ≥14 (Kn/particle) | ≥15 (Kn/particle) |

| Bulk Density (g/cm³) | ≥3.0 | ≥3.1 | ≥3.2 | ≥3.3 |

| Tapped Density (g/cc) | ≥1.9 | ≥2.1 | ≥2.2 | ≥2.3 |

new material

new material