Alumina ceramic teeth offer exceptional hardness, optimized wear resistance, and superior biocompatibility. Designed for dental applications, they ensure reliable durability, extended lifespan, and precise structural integrity for prosthetic restorations.

Product Overview:

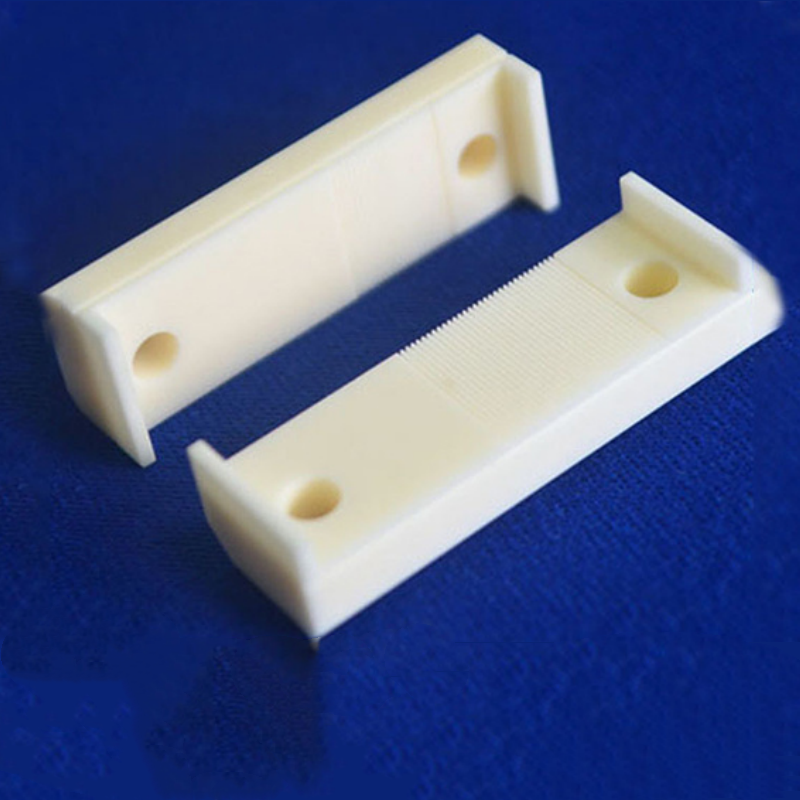

The alumina ceramic teeth are made from high-purity alumina ceramic material, precisely machined to offer exceptional wear resistance, corrosion resistance, and high hardness. These ceramic teeth are particularly suitable for industrial applications that require long-term wear resistance. Their stability and high performance in harsh working environments make them a critical wear-resistant component in various industrial machinery, especially under high load, high-temperature, and high-pressure operating conditions.

Product Features:

- High Hardness:With a Rockwell hardness of HRA80-90, the hardness is close to that of diamond, far superior to wear-resistant steel and stainless steel, ensuring excellent wear resistance.

- Outstanding Wear Resistance:The wear resistance is 266 times that of manganese steel and 171.5 times that of high cast iron, significantly extending equipment lifespan.

- Lightweight Design:The density is 3.5 g/cm³, which is only half that of steel, effectively reducing the equipment load and enhancing overall efficiency.

- Precision Machining:With a machining precision of ±0.01, the tooth shape and structure are accurately maintained, ensuring efficient operation.

- High Temperature Resistance:These ceramic teeth are suitable for high-temperature working conditions and can perform reliably in extreme environments.

Applications:

- Mining Machinery:Used in crushers, grinding machines, and other equipment as wear-resistant components, improving equipment efficiency and lifespan.

- Ceramics Industry:Widely used in ceramic production equipment to increase production efficiency and extend equipment service life.

- Cement Industry:Applied in ball mills, grinding equipment, and other high-wear environments, reducing equipment maintenance and replacement frequency.

- Chemical Equipment:Used in high-strength, wear-resistant industrial equipment such as heating and catalytic systems, enhancing stability and durability.

new material

new material